UV DTF Gangheet has revolutionized the printing industry with its unique blend of Direct-to-Film (DTF) technology and ultraviolet (UV) curing methods. This exciting technique allows for the production of vibrant, durable prints on a wide array of surfaces, from textiles to hard materials like plastic and glass. In this guide, we’ll delve into essential UV printing tips and DTF printing techniques that can help beginners grasp the fundamentals quickly and effectively. Understanding UV DTF printing is vital for anyone looking to launch a successful printing business or enhance their existing skills. Join us as we explore the intricacies of gangheet printing and provide valuable insights to ensure your printing journey is a successful one.

According to modern terminology, UV DTF printing, or Ultra Violet Direct-to-Film printing, represents an innovative solution in the digital print sector, merging the benefits of DTF methodologies with advanced UV light curing. This method, also referred to in some circles as gangheet printing, is pivotal for achieving stunning outputs characterized by bright colors and long-lasting finishes. By mastering gangheet printing techniques, users can unlock new potential in creating diverse product offerings that satisfy a broad market demand. This guide serves as a comprehensive resource for beginners, highlighting various strategies and UV DTF starter tips essential for navigating this emerging niche in the printing world. Understanding and optimizing the process will empower new printers to make an impactful mark within the industry.

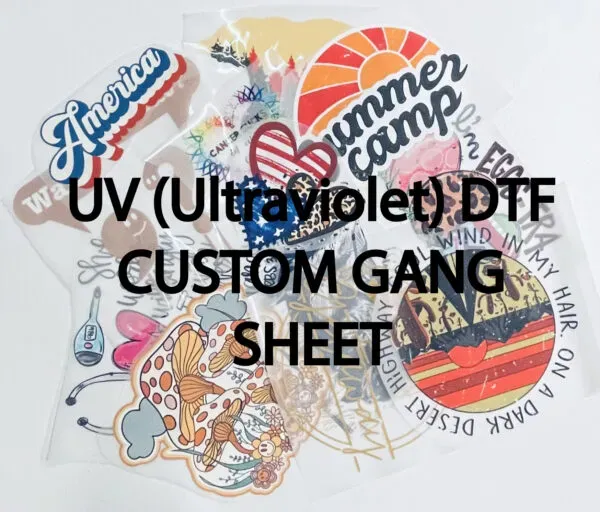

Understanding the Essentials of UV DTF Printing

UV DTF printing, short for UV Direct-to-Film printing, represents a cutting-edge technique that combines the benefits of traditional DTF printing and UV curing. This process primarily involves printing designs onto a special film using UV-reactive inks before transferring them onto various substrates. Through exposure to UV light, the inks cure rapidly, ensuring that they bond effectively to materials such as textiles, plastics, and metals. This dual approach not only enhances the vibrancy of the prints but also ensures their durability, making UV DTF a favored choice among printing professionals.

For those new to the world of printing, understanding the essentials of UV DTF can open up a plethora of creative possibilities. The technology has expanded the range of printable substrates, from fabrics to promotional items, providing businesses with the flexibility to offer customized solutions. Additionally, as the demand for high-quality, durable prints continues to rise, mastering UV DTF will become increasingly advantageous for both hobbyists and entrepreneurs. By familiarizing oneself with the intricacies of this process, you can better appreciate what it takes to produce stunning, lasting designs.

Key Benefits of Incorporating UV DTF Gangheet Techniques

Incorporating UV DTF Gangheet techniques into your printing arsenal can have transformative effects on your projects. One of the standout benefits of this method is its versatility. Unlike traditional printing approaches, UV DTF gangheet allows for printing on a myriad of surfaces, from hard substrates like wood and metal to soft materials like cotton and polyester. This robustness ensures that creators have the flexibility to explore diverse product offerings, immersing themselves in various sectors of the market.

Another crucial aspect is the improved durability and quality of prints that UV DTF gangheet provides. The curing process used in this method enhances ink adhesion, resulting in prints that do not easily fade or wear off, even when exposed to harsh conditions. This durability factor not only minimizes returns and complaints from customers but also maximizes profitability for printing businesses. Therefore, investing time to learn and perfect UV DTF gangheet techniques can lead to both improved customer satisfaction and heightened market presence.

Choosing the Right Equipment for Effective UV DTF Printing

Investing in the right equipment is paramount when establishing a UV DTF printing setup. Begin by selecting a printer that is specifically designed for UV DTF applications, as having the appropriate technology is crucial for achieving consistent results. Look for machines that offer precision in ink drop technology and a diverse range of media compatibility. A printer equipped with advanced features ensures not only speed and efficiency but also adeptness in handling intricate designs.

Additionally, pay attention to the quality of inks and transfer films, as these are equally important in the UV DTF printing process. Using high-quality UV inks formulated for DTF ensures vibrant colors that stand the test of time. Complementing this with compatible transfer films will significantly enhance the overall print quality and adhesion to surfaces. By choosing the right equipment from the outset, you set a solid foundation for producing superior results in UV DTF printing.

Best Practices for Successful UV DTF Printing

To achieve optimal results in UV DTF printing, applying best practices is key. One essential practice involves thorough preparation of both the printing equipment and the substrates. Always begin with cleaning surfaces to remove dust, oils, and other contaminants that can impede the adhesion of inks. Following this, consider priming non-porous materials, as this can significantly boost ink bonding and improve overall print quality. These preparations create a solid groundwork for successful prints.

Experimenting with various settings is another best practice that can yield substantial benefits. Adjusting parameters like ink density and curing times based on the substrate will allow you to identify the optimal conditions for each material. Initially, performing test prints can help gauge the reaction of the ink under different curing durations, ensuring that you arrive at the perfect settings that enable both vibrant colors and durability.

Common Mistakes to Avoid in UV DTF Printing

As with any specialized technique, there are common pitfalls in UV DTF printing that beginners should be cautious of. One frequent mistake is rushing through the preparation phase, which can lead to poor ink adhesion and unsatisfactory prints. Neglecting to clean and properly prepare the substrates can result in issues like peeling or fading, ultimately compromising the quality of the final product. Taking the time to meticulously prep your materials will pay off with superior print results.

Another mistake that often arises is not fully understanding the capabilities and limitations of the printing equipment. This includes misjudging the required settings for specific substrates or being unaware of which inks work best with certain materials. To avoid this, familiarize yourself with your printer’s documentation and engage with the UV DTF community for insights into optimizing performance based on real-world experiences. Staying informed and willing to learn will safeguard against these common printing challenges.

Engaging with the UV DTF Printing Community for Growth

Engaging with the UV DTF printing community can be an invaluable resource for both novice and experienced printers. Online forums, social media groups, and local meetups provide platforms for sharing knowledge, troubleshooting issues, and exploring new techniques. By participating in these communities, you open yourself up to a wealth of information, including tips from seasoned professionals who have navigated similar challenges. This interaction not only fosters camaraderie but also inspires creativity and innovation.

Furthermore, many established printing professionals regularly share tutorials and insights about UV DTF printing processes, which can significantly advance your skill set. Accessing these resources allows you to stay informed about the latest trends, tools, and techniques in the industry. Whether you’re looking to improve your craft or seeking advice on specific problems, being involved in the UV DTF printing community is a proactive way to accelerate your growth in the field.

Frequently Asked Questions

What are the essential UV DTF printing tips for beginners?

For beginners in UV DTF printing, it’s crucial to understand the basic process, which includes design creation, film printing, and transfer application. Make sure to choose equipment specifically tailored for UV DTF, use premium inks, and select high-quality transfer films for optimal print results. Preparation, maintenance, and engaging with the community for tips are also key to success.

What is the best equipment for UV DTF Gangheet printing?

The best equipment for UV DTF Gangheet printing includes a reliable UV DTF printer that suits your production needs, premium inks designed for UV DTF applications, and high-quality DTF transfer films. Investing in quality equipment will significantly enhance your print quality and efficiency.

How do I prepare surfaces for UV DTF printing?

Preparing surfaces for UV DTF printing involves thorough cleaning to remove any contaminants that may affect ink adhesion. Additionally, applying a primer on non-porous surfaces, like plastics and glass, can enhance the ink bonding during the printing process.

What are the key benefits of using UV DTF printing techniques?

UV DTF printing techniques offer several benefits, including versatility, as they can be applied to various substrates. The UV curing process ensures durable prints with vibrant colors, and it allows for quicker production times compared to traditional printing methods.

How does UV curing impact the quality of DTF prints?

UV curing is essential in UV DTF printing as it enhances ink adhesion and longevity, resulting in high-quality prints that resist fading and wear. By effectively curing the inks with UV light, the final products not only appear vibrant but also maintain their quality over time.

What community resources are available for UV DTF Gangheet printing enthusiasts?

There are numerous community resources available for UV DTF Gangheet printing enthusiasts, including online forums, social media groups, and tutorials. Joining these communities allows printers to share experiences, troubleshoot issues, and exchange tips that can greatly enhance their printing skills and knowledge.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A printing technique that uses UV light to cure inks on various substrates, allowing for vibrant, durable designs. |

| Key Benefits | 1. Versatility: Can be used on multiple surfaces. 2. Durable Prints: Resistant to fading and wear. 3. Efficient Production: Faster production times than conventional methods. |

| Tips for Beginners | 1. Understand the basic process: Design, print, transfer. 2. Choose the right equipment: Quality printer, inks, and films. 3. Preparation is key: Clean and prime surfaces. 4. Best practices: Experiment with settings and curing times. 5. Maintenance: Regular cleaning and software updates. 6. Engage with the community: Networking and resources. |

Summary

UV DTF Gangheet offers a transformative approach to digital printing, allowing users to create stunning, durable designs that cater to a wide array of materials. This guide has illuminated the essential aspects of UV DTF printing, from understanding the intricacies of the process to selecting the best equipment and implementing best practices. By honing your skills and remaining engaged with the UV DTF printing community, you will not only enhance your capabilities but also position yourself for success in this rapidly evolving industry. As you embark on your journey in UV DTF Gangheet, remember that continuous learning is key to unlocking the full potential of this innovative printing technique.