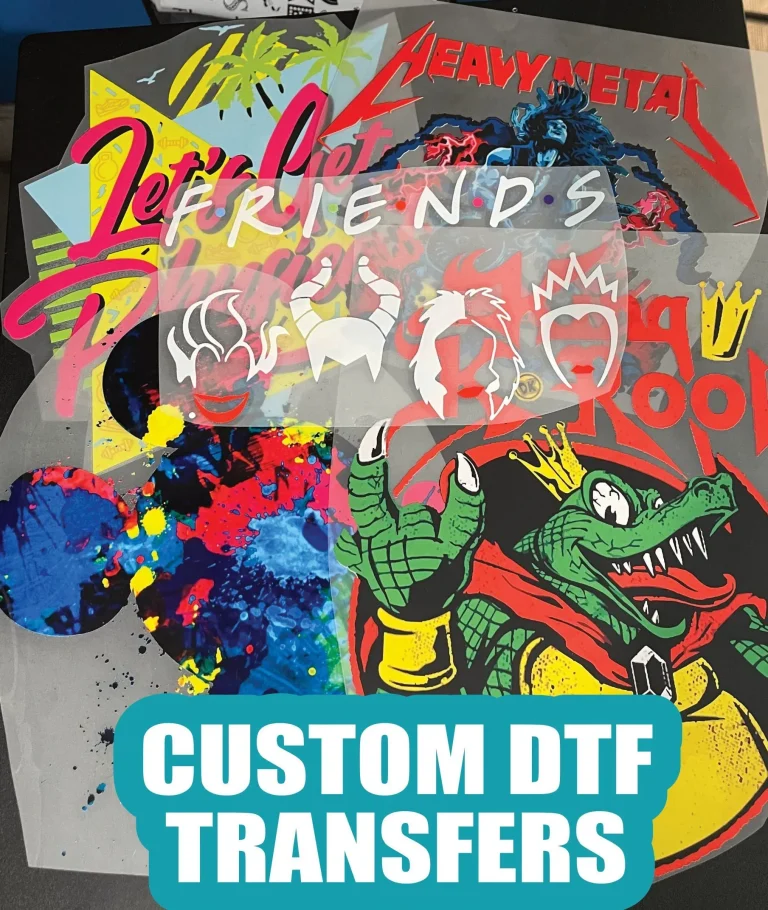

DTF transfers are revolutionizing the DIY fabric printing landscape, offering crafters an exciting way to bring their creative visions to life. This innovative method, known as Direct to Film printing, allows you to apply vibrant fabric designs with ease and precision, making it an ideal choice for both beginners and experienced artists alike. Whether you’re learning how to use DTF transfers for custom apparel or crafting unique home décor, this technology enables stunning results that are sure to impress. In this guide, you will discover the secrets to successfully utilizing DTF transfers in your projects, ensuring that each piece you create is as colorful and detailed as your imagination permits. Join us as we explore this dynamic craft and inspire your next creative DTF projects!

In the realm of fabric design, exploring direct print techniques can unlock a trove of artistic possibilities. The process involving film application for vibrant transfers has become a popular choice for enthusiasts looking to enhance their projects. With a focus on DIY fabric applications, artists are now equipped to create stunning visuals on various materials effortlessly. This approach not only simplifies the creation of visually striking designs but also lays the foundation for countless creative initiatives. Embrace this exciting printing technology to elevate your craft and bring your imaginative ideas to fruition!

Understanding the Basics of DTF Printing

Direct to Film (DTF) printing has emerged as a revolutionary technique in the world of fabric printing. This method allows for vibrant colors and intricate designs to be transferred onto various fabric types with ease. Unlike traditional printing methods that may limit the colors or details achievable, DTF printing utilizes a specialized printer that combines high-quality inks and a unique transfer film. Understanding the basics of DTF printing not only equips you with the necessary knowledge to dive into DIY projects but also opens the door to endless creative possibilities.

The process begins by printing your design onto this special transfer film, which is then layered with adhesive powder to enhance adhesion to the fabric. This approach is particularly advantageous for those who wish to experiment with vibrant fabric designs, as DTF allows for detailed graphics that mimic professional prints. Furthermore, the versatility of DTF printing means it can be applied to different materials, including cotton, polyester, and mixed fabrics, making it an excellent choice for a wide range of creative projects.

Essential Materials for DTF Transfers

To get started with your DTF transfers, having the right materials is crucial for achieving successful results. At the core of any DTF project, you will need a compatible DTF printer that works with water-based inks specifically designed for this printing method. In addition to the printer, DTF transfer film is essential; it’s the medium on which you print your designs and ensures that vibrant colors are transferred effectively to the final fabric.

Another key component is the adhesive powder, which is applied immediately after printing your design onto the film. This powder is vital for creating a strong bond between your printed design and the fabric. Additionally, you should invest in a quality heat press machine. Unlike household irons, a heat press offers consistent heat and pressure, which is necessary for achieving a professional finish and ensuring that your prints last through multiple washes without fading or cracking.

Step-by-Step Guide to Using DTF Transfers

Using DTF transfers may seem daunting at first, but with a step-by-step approach, it becomes an attainable and enjoyable craft. Begin by designing your image, ensuring that it is mirrored before printing since the final transfer will be a reflection of what you see on your screen. It’s essential to select high-resolution images to ensure your project is as vibrant and detailed as possible. Once your design is ready, print it onto the DTF film, carefully applying the adhesive powder right after to ensure full coverage.

The next steps involve curing the ink, which can be achieved through a heat press or a conveyor dryer. Proper curing is necessary to solidify the adhesive and ensure it will hold securely to the fabric. After curing, position your transfer film onto the fabric and then press it with the heat press. This process often requires a specific temperature and timing depending on the type of fabric used. Finally, allow the transfer to cool slightly before peeling the film away to reveal your stunning design!

Caring for Your DTF Printed Fabrics

After completing your DTF transfer project, proper care for your printed fabrics is essential to maintain their integrity and vibrancy over time. Initially, it’s recommended to refrain from washing the fabric for at least 24 hours after the heat transfer. This waiting period ensures that the adhesive has fully bonded with the fabric, thus preventing any premature peeling or fading of the design.

When it comes to washing your DTF printed items, always opt for cold water and turn garments inside out to protect the printed side. Avoid using bleach or harsh detergents that may compromise the quality of the print. Additionally, tumble drying should be done on low heat or, better yet, line dry to preserve both the fabric and the design’s brightness. Following these care guidelines will ensure that your creative DTF projects maintain their stunning appearance for countless uses.

Creative Project Ideas Using DTF Transfers

DTF transfers provide endless possibilities for creativity, making them a go-to option for DIY enthusiasts. One exciting project idea is to customize T-shirts with unique graphics or personal quotes, perfect for family gatherings, events, or gifts. You can easily create matching outfits by printing similar designs for groups. Not only does this foster a sense of unity, but it also showcases your creativity through personalized fashion.

Another innovative use for DTF transfers is in designing home decor items, such as pillows or tote bags. By printing vibrant, eye-catching designs, you can easily breathe new life into your living space or create memorable custom gifts. The flexibility of DTF printing allows for experimentation with various fabrics and aesthetics, encouraging you to explore your artistic side. Whether it’s a quirky design for a friend or a personalized piece for your home, DTF transfers can help bring your visions to life.

Exploring Resources for DTF Transfer Projects

As you embark on your journey into the world of DTF transfers, taking advantage of available resources can significantly enhance your learning experience. Online communities, such as forums and social media groups dedicated to crafting and DTF printing, offer a wealth of information. These platforms allow you to connect with fellow crafters, share tips, ask questions, and even showcase your completed projects for feedback.

Additionally, numerous blogs and YouTube channels provide step-by-step tutorials, project ideas, and troubleshooting advice specifically for DTF printing. Resources like the Craft Industry Alliance and T-Shirt Magazine frequently publish articles that cover a range of topics related to DTF techniques, ensuring you remain updated on best practices and innovations in the industry. Embracing these resources will not only boost your confidence but also inspire you to explore more creative DTF projects!

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a method of printing designs onto a special film that can then be transferred onto fabrics. The process involves using a DTF printer to create vibrant prints on transfer film, applying adhesive powder, and utilizing a heat press to permanently bond the design to the fabric. This technique allows for high-quality, detailed, and colorful fabric designs.

How do I use DTF transfers for my DIY projects?

Using DTF transfers for DIY projects involves several key steps: first, print your design using a compatible DTF printer on transfer film. Next, apply adhesive powder to the wet ink, cure the print using a heat press or conveyor dryer, and then transfer the design onto your fabric using heat. After cooling, peel off the film to reveal your vibrant fabric design.

What materials do I need for DTF printing?

To successfully execute DTF printing, you will need a DTF printer compatible with water-based inks, transfer film designed for DTF printing, adhesive powder to bond the design, and a heat press machine to apply heat and pressure for transfer. Having these materials ensures a smooth and effective DTF transfer process.

How long does the DTF transfer process take?

The DTF transfer process duration varies but typically includes printing, applying adhesive, curing, and heat pressing. Overall, expect the process to take about 30 minutes to an hour, depending on your setup and fabric type. Allow additional time for curing the design after the transfer to ensure durability.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers are versatile and can be applied to a variety of fabrics, including cotton, polyester, and fabric blends. This flexibility makes DTF printing an excellent choice for custom apparel, household items, and creative fabric projects. Ensure the fabric is compatible with your chosen transfer settings for optimal results.

What are the benefits of using DTF printing for fabric projects?

DTF printing offers numerous benefits, including the ability to produce vibrant and detailed fabric designs. It is versatile, allowing application on various fabric types, and provides durability, making designs resistant to cracking and fading. This technique is ideal for DIY enthusiasts looking to achieve professional-quality results in their fabric projects.

| Key Points | Details | |

|---|---|---|

| What are DTF Transfers? | A modern method for applying designs onto fabrics using a DTF printer and heat press. | |

| Materials Needed | DTF Printer, Transfer Film, Adhesive Powder, Heat Press Machine. | |

| Process Steps | 1. Print the design on transfer film (mirror image). 2. Apply adhesive powder. 3. Cure the ink. 4. Heat transfer the design. 5. Peel off the film. 6. Let it cure. | |

| Advantages | Vibrant colors, versatility on different fabrics, and durability against wear and tear. | |

Summary

DTF Transfers have revolutionized the world of fabric crafting by offering a unique and vibrant way to transfer designs onto various materials. By following the essential steps outlined in this guide, you can utilize DTF transfers to achieve stunning results for your creative projects, whether it’s clothing, home decor, or custom fabric designs. The durability and detail of DTF transfers set them apart from traditional methods, allowing crafters to explore new horizons in their DIY endeavors. Embrace the innovative nature of DTF transfers and unlock your full potential as a creative artist.