In the fast-evolving world of custom apparel, **DTF transfers**—or Direct-to-Film transfers—are making a significant impact as an innovative printing choice. Unlike traditional techniques such as DTG printing and screen printing, this method prides itself on producing vibrant colors and intricate details without the hassle of pre-treatment. Whether you’re a small business or an entrepreneur seeking to create personalized designs, DTF offers versatility across various fabric types, from cotton to polyester blends. Moreover, the elimination of complex setup processes reduces turnaround time, allowing for quicker production runs. This post will delve into the advantages and challenges of DTF transfers, setting the stage for understanding their role in today’s competitive custom apparel market.

When it comes to custom fabric printing, alternative methods like Direct-to-Film transfers have gained traction alongside well-known techniques such as DTG printing, screen printing, and heat transfer vinyl. Often regarded as a breakthrough in apparel creation, these film-based transfers provide a modern solution to artists and manufacturers seeking high-quality prints. The seamless integration of color and design intricacies ensures that businesses can meet diverse consumer demands efficiently. With the growing emphasis on personalized garments, understanding these various printing alternatives will empower creators to choose the right technique for their unique projects. This article will explore the distinct characteristics and benefits of DTF as compared to traditional printing methods.

Understanding DTF Transfers and Their Process

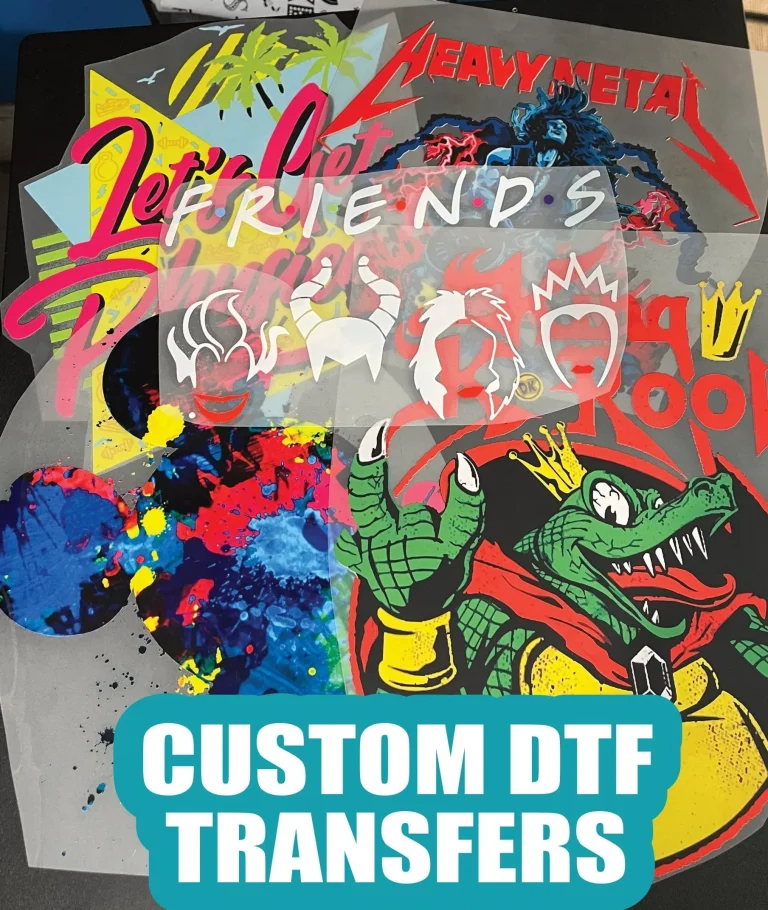

DTF transfers, or Direct-to-Film transfers, represent an innovative method for applying designs to textiles that is rapidly gaining popularity among custom apparel manufacturers. This technique involves printing vibrant designs directly onto a special film, which is then adhered to the fabric using high heat and pressure. Unlike other methods, DTF printing does not require the pre-treatment of the fabric, making it a streamlined option for businesses looking to produce high-quality custom apparel efficiently.

One of the most compelling aspects of DTF transfers is their versatility; they can be printed on various materials, from cotton to polyester blends, and they maintain their vibrancy and detail even after multiple washes. This flexibility makes them suitable for everything from individual custom orders to bulk merchandise production. As the demand for personalized apparel continues to rise, DTF provides a viable solution that merges quality with ease of application.

Comparative Analysis of Printing Methods

When comparing DTF transfers to other printing methods like DTG and screen printing, it’s crucial to consider the unique advantages each technique offers. For instance, while DTG printing excels in reproducing intricate designs with minimal color limitations, it often requires pre-treatment of materials, which can extend production times. In contrast, DTF eliminates this step, allowing for quicker processing and a broader range of compatible fabrics.

Screen printing remains an industry standard due to its durability and cost-effectiveness, particularly for large production runs. However, DTF transfers provide a compelling middle ground, offering similar durability without the extensive setup time required for traditional screen printing. By understanding these distinctions, businesses can make informed choices that best fit their production needs, especially when considering factors like artwork complexity and order quantities.

DTF vs. DTG: Which Printing Method is Right for You?

Direct-to-Garment (DTG) printing has been a popular choice for custom apparel due to its ability to handle complex designs and produce high-quality prints quickly. However, DTG requires pre-treatment for darker fabrics, which adds time and cost to the process. DTF transfers offer an alternative that streamlines production without sacrificing quality. Additionally, DTF can print on a wider variety of fabric blends, providing more options for businesses seeking to diversify their apparel offerings.

Moreover, DTF printing also has the advantage of being less expensive for mid-range quantities, where DTG’s costs can rise sharply. By evaluating the fabric type and order size, businesses can choose between DTF and DTG to maximize efficiency and minimize waste. Furthermore, the advancements in DTF technology make it a continually evolving choice, allowing for increasing quality and durability in prints that keep up with market demands.

The Endurance of DTF Transfers

One of the standout features of DTF transfers is their durability compared to other printing methods like heat transfer vinyl (HTV). While HTV can have its advantages, particularly in quick setups and customizing smaller runs, its longevity can vary based on the quality of materials used. DTF transfers, on the other hand, are becoming known for their resilience against washes and wear, making them a practical choice for items that experience high levels of use, such as uniforms or promotional wear.

Additionally, advancements in the formulation of inks used in DTF printing continue to enhance the durability of prints. Many businesses are beginning to recognize that investing in DTF setups leads to not only superior quality but also long-term savings as the prints maintain their aesthetic over time. As customer expectations for quality increase, the robust nature of DTF transfers positions them favorably against traditional options.

Trends in Custom Apparel Printing: The Rise of DTF

The recent surge in interest towards DTF printing reflects broader trends within the custom apparel industry as consumer demand shifts towards more personalized, high-quality products. As brands strive to cater to individual tastes and preferences, DTF’s capacity to produce vibrant, detailed designs on many fabrics aligns perfectly with these market demands. This trend is expected to escalate, with more businesses adopting DTF technology to keep pace with customization desires.

Furthermore, sustainable practices in printing are increasingly becoming a priority, and DTF printing is evolving in this area as well. Advancements in inks and processes are making DTF an appealing choice for eco-conscious businesses. With a focus on sustainability, many industries are looking into using eco-friendly inks that do not compromise on vibrancy, which is a core benefit of DTF printing.

Choosing the Right Printing Method for Your Needs

Selecting the ideal printing technique hinges on several factors including design complexity, fabric type, and production volume. With its flexibility and vibrant output, DTF transfers are becoming a favorite among small businesses and creatives looking for high-quality results without significant setup costs. On the other hand, methods like screen printing and DTG are indispensable for bulk orders and detailed artwork requiring multiple colors.

Ultimately, understanding your specific needs is key to making the best choice. Analyze factors such as budget, expected turnaround time, and desired print quality. By weighing the strengths and weaknesses of DTF transfers alongside traditional methods, you can confidently select a printing approach that aligns with your brand vision and meets your operational demands.

Frequently Asked Questions

What are DTF Transfers and how do they compare to DTG printing?

DTF Transfers, or Direct-to-Film Transfers, utilize a special film to print high-quality designs that can then be heat applied onto various fabrics. Unlike DTG (Direct-to-Garment) printing, which prints directly onto materials, DTF does not require pre-treatment for dark fabrics, making it a simpler option for custom apparel printing with vibrant results.

Are DTF Transfers more cost-effective than screen printing for bulk orders?

DTF Transfers can have higher initial setup costs due to equipment and materials. However, for smaller runs, they can be more cost-effective than screen printing, which is typically more economical for large quantities due to lower per-unit costs. For small custom orders, DTF might be the better option.

What are the advantages of using DTF Transfers over heat transfer vinyl (HTV)?

DTF Transfers offer greater versatility and the ability to print intricate designs with vibrant colors, which HTV struggles with due to the cutting process. DTF does not have the durability issues that can affect HTV prints, especially when exposed to heavy wear or multiple washes.

What types of fabrics work best with DTF Transfers compared to other printing methods?

DTF Transfers are compatible with a wide range of fabrics, including cotton, polyester, and blends, similar to DTG printing. In contrast, screen printing is generally best suited for thicker materials, while HTV works on various fabrics but may not adhere as well to certain blends, limiting its application.

Can you achieve intricate designs with DTF Transfers like you can with DTG printing?

Yes, DTF Transfers can achieve high levels of detail similar to DTG printing. Both methods are adept at reproducing intricate designs, but DTF does this without needing the pre-treatment that DTG requires, making it a more user-friendly option for custom apparel.

Are DTF Transfers suitable for high volume production runs?

While DTF Transfers are great for small to medium-sized runs due to their quick setup and vibrant results, they may not be as efficient for high volume production compared to screen printing, which excels at producing large quantities at a lower cost per unit.

| Printing Method | Process | Advantages | Limitations |

|---|---|---|---|

| DTF Transfers | Prints high-quality designs onto a special film which is then heat pressed onto fabric. | Versatile on various textiles, vibrant prints, no pre-treatment needed. | High initial setup costs, durability may lag behind traditional methods. |

| DTG Printing | Uses inkjet technology to print directly onto garments. | Excellent for fine detail, quick turnaround for small runs. | Requires pre-treatment for dark fabrics, expensive for bulk orders. |

| Screen Printing | Involves creating stencils for each color and pushing ink through. | Cost-effective for large orders, very durable. | Time-consuming setup for screens, limited in color combinations. |

| Heat Transfer Vinyl (HTV) | Designs are cut from vinyl sheets and heat set onto garments. | Quick customization, variety of finishes available. | Detailed designs may be challenging, durability can be inconsistent. |

Summary

DTF Transfers have become a widely embraced choice in the custom apparel printing industry due to their unique advantages, including versatility and vibrant color output. Unlike traditional printing techniques, DTF allows for an easy transfer process without the need for pre-treatment, making it a favorable option for many businesses. As the demand for personalized apparel continues to surge, understanding the strengths and weaknesses of DTF compared to alternatives like DTG, screen printing, and HTV is essential. With ongoing technological advancements, DTF is poised to maintain a significant presence in the market, catering to the evolving preferences of consumers for quality and customization.