DTF transfers, or Direct to Film transfers, have revolutionized the world of textile printing by offering an innovative way to achieve vibrant prints that stand the test of time. Unlike more conventional methods such as screen printing, DTF printing combines high-fidelity color with outstanding durability, making it a top choice for both businesses and creative individuals. This technique involves printing intricate designs onto a special film, which can later be applied to various fabrics under heat and pressure, resulting in stunning and long-lasting prints. As we delve into the benefits of DTF transfers, it becomes evident that this method is setting a new standard in the industry, merging artistry with practicality. Join us as we explore the incredible capabilities and advantages that DTF transfers bring to the ever-evolving landscape of textile printing.

In the vibrant realm of fabric decoration, methods like Direct to Film (DTF) printing shine for their ability to deliver breathtaking and durable prints. Known for their ease of use, these textile printing solutions allow for the stunning visualization of designs on a wide variety of materials. By utilizing a process that transfers inks from a film to fabric, creators can achieve intricate color gradients and detailed designs that traditional techniques may struggle to replicate. The versatility offered by DTF technology not only enhances creative expression but also caters to the increasing demand for custom apparel. This introduction to the world of DTF printing benefits both artisans and businesses alike, ensuring that their artistic visions can come to life with resilience and flair.

Understanding the DTF Transfers Process

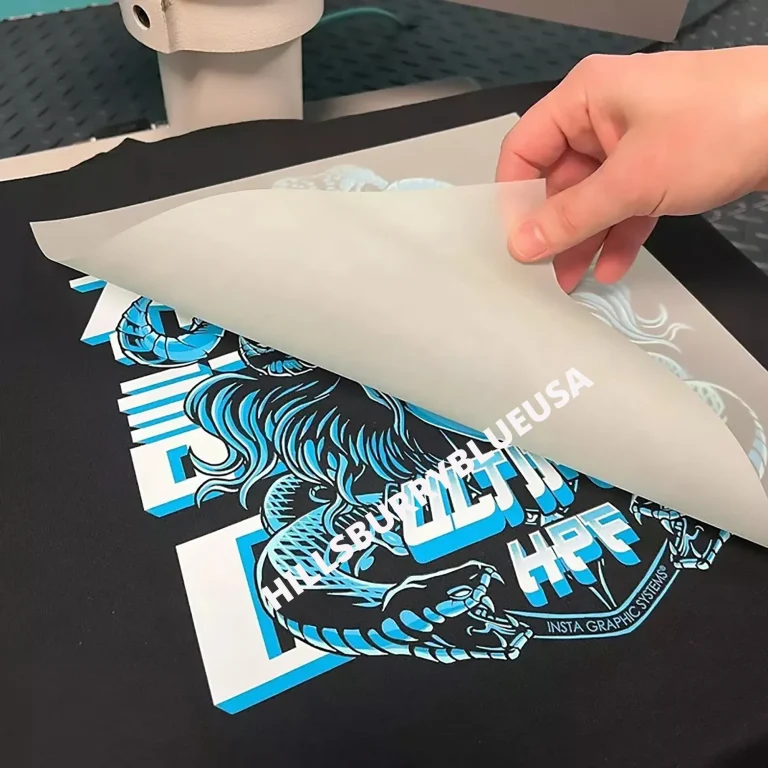

DTF transfers, short for Direct to Film transfers, represent a modern approach to textile printing that combines technology and artistry in a seamless process. The journey begins with the preparation of a digital design that is created using graphic design software. This design is printed onto a special PET film using innovative DTF inks, which are specifically engineered to adhere effectively to both the film and the fabric. After the printing phase, a powdered adhesive is applied, enhancing the bonding capability of the print once subjected to heat and pressure during the heat transfer process.

Once the heat transfer is complete, the result is a stunning display of vibrant colors and intricate details that truly captures the essence of the original design. This process not only facilitates high-quality prints but also ensures that they are durable and long-lasting, capable of enduring frequent wash cycles without showing signs of wear. The versatility of DTF technology allows for various fabric types to be used, making it an ideal realm for both professional businesses and aspiring hobbyists looking to create unique and vibrant prints.

Exploring the Benefits of DTF Printing

One of the standout advantages of DTF printing is its impressive durability. Unlike traditional printing techniques, the prints achieved through DTF transfers are resilient, standing firm against the challenges of washing and wear. This durability ensures that your vibrant prints continue to shine, making them perfect for custom apparel that can withstand everyday use without fading or peeling. This robustness translates into significant value for businesses that offer custom printed items, allowing them to provide quality products that customers can rely on.

In addition to durability, DTF printing presents unparalleled versatility in application. The method allows for prints on a wide range of materials including cotton, polyester, and various blends. This capability opens up countless possibilities for creating diverse products, from dynamic t-shirts to stylish accessories like hats and bags. As the printing world evolves, DTF technology paves the way for businesses to meet the growing demand for customizable products, offering vibrant designs that reflect individual personality and style.

Market Trends Influencing DTF Transfers

The DTF printing market is witnessing a significant surge, particularly among small businesses and startups that aim to diversify their product offerings. This trend stems from the increasing consumer demand for personalized and unique apparel. DTF transfers enable businesses to cater to this shift, allowing them to produce customized items without compromising on quality. Unlike traditional methods that require large quantities for cost efficiency, DTF’s print-on-demand capability offers flexibility that is essential for today’s fast-paced market.

As we approach 2025, it is evident that DTF technology is not merely a trend but a transformative force within the textile printing industry. Companies embracing this technology are better equipped to respond to the evolving consumer preferences for individualized products. The ability to create tailored items not only strengthens customer relationships but also positions brands strategically in a market that increasingly values uniqueness and quality.

Technological Innovations Advancing DTF Printing

Technological advancements are at the heart of the evolution of DTF transfers, driving both quality and efficiency to new heights. Improvements in ink formulations have resulted in DTF inks that not only provide vibrant colors but are also eco-friendly, reducing the environmental impact of the printing process. These innovations ensure that prints remain vivid and durable, opening the door for even more creativity in design offerings.

Additionally, automation in the production process has significantly enhanced the workflow for DTF printing. New printer designs and advanced software streamline operations, leading to quicker turnaround times and improved print consistency. Such enhancements are crucial for businesses looking to maintain a competitive edge in a fast-evolving market. As DTF technology continues to upgrade, it promises exciting opportunities for both creators and consumers alike.

The Role of Sustainability in DTF Transfers

Sustainability is becoming an increasingly important consideration within the printing industry, and DTF transfers are no exception. As consumer awareness regarding environmental issues grows, many manufacturers are committed to adopting eco-friendly practices in the production process. This includes the exploration of sustainable inks and materials for DTF transfers, aimed at minimizing the overall carbon footprint associated with textile production.

Implementing sustainable practices not only benefits the environment but also enhances the appeal of brands among environmentally-conscious consumers. Companies that prioritize sustainability in their offerings are likely to develop stronger customer loyalty and attract a new segment of the market that values ethical production. Thus, integrating sustainability into DTF printing practices is not just beneficial for the planet but is also a strategic move for business success.

DTF Transfers vs. Traditional Printing Methods

When comparing DTF transfers to traditional printing methods such as screen printing and direct-to-garment (DTG) printing, the differences in quality and application methods become apparent. DTF transfers offer a higher level of detail and vibrancy that many traditional methods struggle to achieve. The ability to produce intricate designs with gradients and sharp contrasts allows creators to push the boundaries of textile printing, appealing to a wider range of artistic ventures.

Additionally, DTF printing minimizes waste by allowing for small batch orders, making it a more economical choice for those looking to produce limited runs without the financial burden often associated with traditional methods. This cost-effectiveness, combined with the durability and versatility of DTF prints, positions this modern method as a preferred option for many businesses and artists dedicated to creating high-quality textile products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film printing, involve printing vibrant designs onto a special PET film, which is then applied to fabric using heat and pressure. The process includes printing the design, applying a powdered adhesive, and using a heat press to bond the print to the textile, resulting in long-lasting prints.

What are the benefits of using DTF printing for textile printing?

DTF printing offers several benefits including exceptional durability of prints that withstand multiple washes, versatility to print on various fabrics, vibrant colors for eye-catching designs, and cost-effectiveness for small batch production compared to traditional methods.

Can DTF transfers be used on any type of fabric?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabric types including cotton, polyester, and their blends, making it suitable for diverse textile printing applications.

How do DTF transfers compare to traditional screen printing?

Unlike traditional screen printing, DTF transfers provide vibrant prints with intricate details, are more flexible for small batches, and require less setup time, offering a cost-effective solution for custom and on-demand textile printing.

What makes DTF printing a sustainable choice for businesses?

DTF printing is considered more sustainable as it minimizes waste, allows for print-on-demand capabilities, and manufacturers are increasingly using eco-friendly inks, reducing the environmental impact associated with textile production.

How do I ensure the quality of DTF transfers for my designs?

To ensure high-quality DTF transfers, use compatible graphic design software for preparing your digital files, choose reliable DTF printers and inks, follow the correct printing and heat transfer processes, and select appropriate fabric types to achieve vibrant and long-lasting prints.

| Aspect | Details |

|---|---|

| Definition | DTF (Direct to Film) transfers are a printing method that involves printing designs on a special film which is then applied to fabric using heat. |

| Process | 1. Design Preparation: Create a digital design. 2. Printing on Film: Print the design on PET film. 3. Heat Transfer: Apply the film to fabric using heat and a press. |

| Advantages | 1. Durability: withstands multiple washes. 2. Versatility: applies to various fabrics. 3. Vibrant Colors: produces rich colors. 4. Cost-Effective: ideal for small batches. |

| Market Trends | Growing popularity among small businesses and startups due to increased customer demand for customization and flexibility in small batch production. |

| Technological Innovations | Improvements in ink formulations and automation of printing processes are enhancing quality and efficiency. |

| Environmental Considerations | Focus on eco-friendly inks and materials to appeal to environmentally-conscious consumers. |

Summary

DTF transfers are revolutionizing the world of fabric printing with their ability to produce vibrant and long-lasting prints. This innovative technology not only enhances the quality of designs but also offers remarkable versatility, allowing a variety of fabric types to be printed upon. As the demand for customization increases, businesses are leveraging DTF transfers to meet consumer expectations while embracing cost-effective and sustainable practices. The integration of advanced technologies continues to drive the evolution of DTF transfers, ensuring their position as a leading choice for creative expression in the textile industry.