In recent years, DTF transfers, or direct-to-film transfers, have emerged as a groundbreaking solution in the printing industry, reshaping how businesses approach custom prints. Unlike traditional printing methods, DTF printing benefits from its ability to produce high-quality, vibrant designs that adhere well to a variety of materials, including textiles and hard surfaces. As consumers increasingly demand personalization, custom DTF prints have gained traction, offering a quick and efficient way to meet individual preferences. In addition to their exceptional quality, DTF transfer technology is more cost-effective compared to screen printing, allowing even small businesses to thrive without hefty upfront costs. This blog post will delve into the numerous advantages of DTF transfers and reveal why they’re becoming the preferred choice for entrepreneurs and brands alike.

As the printing landscape evolves, direct-to-film (DTF) printing has captured attention for its innovative approach to delivering stunning graphics on various products. This technique, often referred to in terms like DTF technology and custom film transfers, offers unique benefits that set it apart from traditional methods. With its quick turnaround and flexibility, the DTF printing process caters to today’s demand for unique and personalized items, making it favorable for both small artisans and large-scale manufacturers. The growing interest in DTF prints stems not only from their visual appeal but also from their durability and cost efficiency, contributing to their rise as a preferred choice in print production. In this overview, we’ll explore how this cutting-edge printing method is transforming the way businesses create and deliver their products.

The Versatility of DTF Transfers in Various Industries

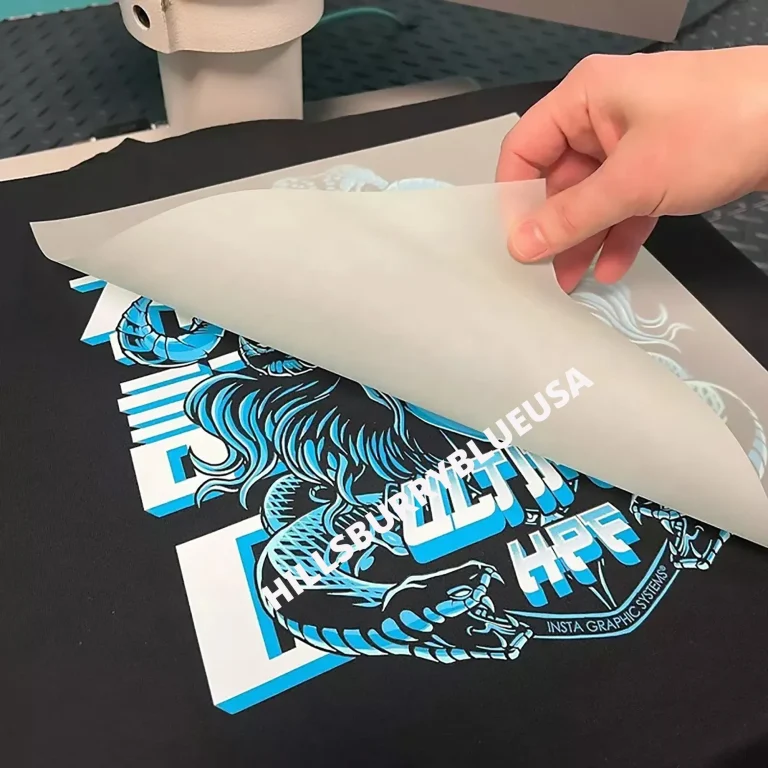

DTF transfers are celebrated for their unparalleled versatility, allowing businesses to tap into a multitude of industries. From apparel to home décor, DTF technology can be effectively utilized across various materials and products. Whether it’s creating stunning t-shirts, promotional bags, or even custom headwear, the adaptability of DTF transfers enables businesses to meet diverse customer demands without compromising quality. This capacity to print on substrates like cotton, polyester, and blends not only expands the product range but also ensures that small businesses and large manufacturers alike can flourish in competitive markets.

Moreover, the flexibility inherent in DTF printing supports bespoke designs, catering to niche markets that value personalization. With the unique capability to produce both small and large runs, businesses can quickly pivot to meet fluctuations in market trends. The versatility of DTF transfers positions them as a favorable choice for businesses looking to innovate and diversify their offerings, securing a strong foothold in various sectors.

Frequently Asked Questions

What are the main benefits of using DTF transfers in printing?

DTF transfers offer numerous benefits including high-quality prints, versatility on various materials, cost-effectiveness compared to traditional printing, and an eco-friendly production process with water-based inks. These advantages make DTF printing an attractive choice for businesses that prioritize quality and sustainability.

How does DTF printing compare to traditional printing methods?

DTF printing differs from traditional methods like screen printing by providing greater versatility and shorter setup times. DTF transfers can produce vibrant, durable prints with less waste, making them a more efficient and cost-effective option for short runs and customized orders.

Can I customize DTF prints for unique designs?

Absolutely! Custom DTF prints are one of the standout features of DTF technology. It allows businesses to create unique, personalized designs catered to individual customer preferences, making it a perfect choice for custom merchandise and special events.

Is DTF transfer technology eco-friendly?

Yes, DTF transfer technology is considered eco-friendly as it typically uses water-based inks that are free from harmful solvents. This reduces environmental impact compared to traditional printing methods, aligning well with the growing consumer demand for sustainable practices.

What types of materials can DTF transfers be applied to?

DTF transfers are highly versatile and can be applied to a variety of materials including cotton, polyester, and cotton-poly blends. This flexibility allows for a wide range of applications, from t-shirts to bags and more, catering to diverse market needs.

What is the minimum order quantity for DTF printing?

One of the key benefits of DTF printing is its flexibility regarding order quantities. Companies can produce custom DTF prints on demand without the burden of minimum order requirements, making it particularly advantageous for small businesses or those testing new designs.

| Key Points | Explanation |

|---|---|

| Versatility | DTF transfers can be applied to various materials, making them suitable for a broad range of products. |

| High-Quality Prints | They provide vibrant colors and intricate details, maintaining integrity over time. |

| Cost-Effectiveness | Lower setup costs and ability to run small batches make them ideal for startups. |

| Ease of Use | A simplified workflow allows quicker turnaround times, providing a competitive edge. |

| Eco-Friendliness | Many inks are water-based and competitive with traditional printing in sustainability. |

| No Minimum Order Quantity | Allows businesses to print on-demand and adapt production to actual demand. |

| Durability of DTF Prints | Resistant to abrasion and fading, ensuring long-lasting product quality. |

| Opportunities for Customization | Supports personalized designs, catering to individual client needs. |

| Technological Advancements | Ongoing innovations in technology enhance the effectiveness of DTF printing. |

| Seamless Integration | Minimal disruption allows for smooth incorporation into existing processes. |

Summary

DTF transfers are reshaping the printing industry landscape, marking a shift towards more efficient and customizable print solutions. This technology’s versatility allows it to be used across diverse materials, while its high-quality outputs ensure durability and vibrant graphics that meet consumer expectations. Cost-effective and eco-friendly, DTF transfers eliminate the burden of minimum order quantities, enabling businesses to adapt swiftly to market demands. In essence, embracing DTF transfers provides companies with the opportunity to enhance their product offerings and stay competitive in an ever-evolving market.