The DTF printing process has emerged as a game-changer in the world of garment decoration, enabling unparalleled design versatility and quality. Direct-to-film printing, or DTF, utilizes innovative technology to transfer vibrant images onto various fabrics efficiently. This advanced method allows for intricate multi-colored designs without the cumbersome setup required by traditional screen printing. With its rapid turnaround and impressive durability, it’s no wonder both hobbyists and professional printers are welcoming the benefits of DTF printing into their arsenals. In this guide, we will delve deeper into how DTF printing works, the essential equipment needed, and compare it with sublimation techniques to help you make the best choice for your printing needs.

Exploring the realm of digital textile printing reveals the revolutionary technique known simply as direct-to-film, or DTF. This modern approach has captivated the textile printing industry, thanks to its ability to produce sharp graphics with rich color directly on fabric surfaces. By leveraging advanced printing equipment, DTF ensures maximum efficiency and high-quality results that cater to a wide range of materials. This method stands out in comparisons with other printing techniques such as sublimation, particularly due to its versatility and long-lasting impact on the fabric. As we navigate through this discussion, you’ll uncover not only the fundamental mechanics of how DTF technology operates, but also why it’s rapidly becoming a preferred choice for designers and manufacturers alike.

The DTF Printing Process Explained

Understanding the DTF printing process is fundamental for anyone venturing into garment decoration. At its core, Direct-to-Film (DTF) printing involves transferring designs onto amulti-colored film before applying them to fabric. This method begins with printing the artwork onto a specialized PET film using eco-solvent inks that provide clarity and vibrancy. The subsequent step involves applying a thermoplastic adhesive, which is essential for ensuring the print will bond effectively to the fabric during the heat press application.

The intricacies of how DTF printing works encompass more than just the layering of colors on film. Each stage requires precision, from selecting the right inks to adjusting the heat press settings for optimal adhesion. Moreover, this technology supports printing on various materials, not limiting the creations to cotton alone; other fabrics, including polyester blends, can be printed with exceptional quality. This opens up creative avenues for fashion designers and decorators, allowing for unique and durable fashions.

Benefits of DTF Printing

DTF printing offers an array of advantages that make it increasingly popular among garment decorators. The primary benefit is its ability to deliver high-quality prints with outstanding color vibrancy and detail. This quality is particularly evident when comparing DTF vs. sublimation; while sublimation excels on synthetic fabrics, DTF’s adaptability to multiple fabric types is unmatched. Whether a designer is working on cotton t-shirts or poly blends, DTF printing ensures a consistent finish that withstands the test of time.

Moreover, the cost-effectiveness of DTF printing is a significant lure for both small businesses and larger operations. With lower setup costs compared to traditional screen printing, entrepreneurs can efficiently handle both custom orders and bulk requests without incurring excessive expenses. The quick turnaround time associated with DTF printing enables businesses to respond rapidly to market demands, cementing their position in the ever-evolving textile landscape.

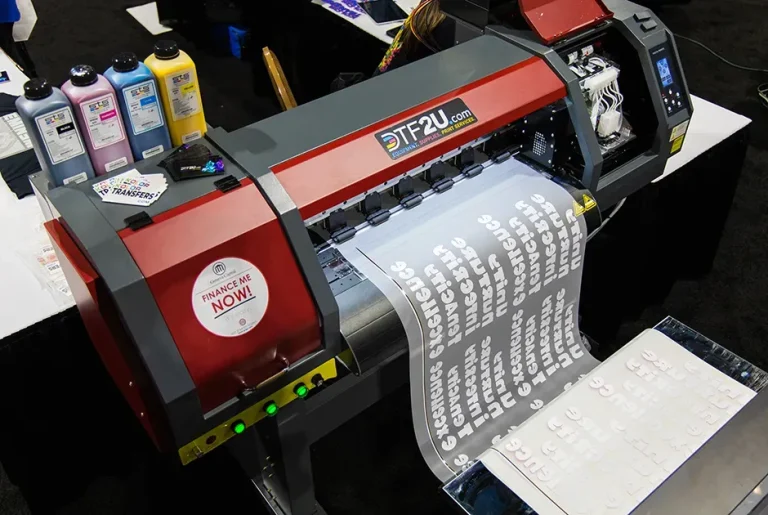

Equipment Needed for DTF Printing

Investing in quality DTF printing equipment is crucial for achieving superior results. Essential tools include DTF printers designed to perform intricate printing tasks with high resolution. These printers are typically compatible with eco-solvent inks which provide vibrant colors and durability, essential for commercial applications. Additionally, a heat press is necessary for transferring designs onto various fabrics. This equipment allows users to apply the correct pressure and heat, ensuring adherence and longevity of the prints.

Alongside printers and heat presses, the adhesive powder is also a vital component. This thermoplastic adhesive powder is sprinkled onto the printed film while the ink is still wet, creating a bond that holds up over time. Selecting quality supplies is instrumental in maintaining the benefits of DTF printing, ensuring that end products do not fade, crack, or peel easily. As such, anyone eager to begin should prioritize sourcing reputable brands for their DTF printing equipment.

Differences Between DTF and Sublimation Printing

Understanding the differences between DTF and sublimation printing can guide users in selecting the best method for their projects. While both techniques offer vibrant color reproduction, their applications and materials differ significantly. DTF printing excels on a wider range of fabrics, including cotton and blends, making it more versatile for various garment types. In contrast, sublimation is primarily effective on synthetic materials, which can limit creative possibility for some projects.

Another fundamental difference lies in the printing process itself. DTF printing involves printing designs onto a film and then transferring them to fabric, while sublimation directly dyes the fabric using heat to infuse the ink into the material itself. This process produces fade-resistant colors, but it is constrained to poly or polyester-based fabrics. By understanding these distinctions, designers can effectively choose which technique best suits their needs, balancing factors such as cost, fabric type, and desired outcomes.

Getting Started with DTF Printing

For anyone eager to dive into DTF printing, the initial steps involve thorough research into the required equipment and techniques. First, sourcing high-quality DTF printers and compatible inks is essential for producing professional results. As the market is flooded with options, taking the time to read reviews and seek recommendations can lead new users to reliable equipment that matches their budget and needs.

Next, it’s beneficial to acquire foundational skills and knowledge of the DTF printing process. Engaging in online courses or tutorials can be invaluable, providing insight into the nuances of printing and transferring artwork. Additionally, experimenting with graphic design software to create original designs can refine skills and inspire creativity, making the transition from novice to expert much smoother.

The Future of DTF Printing in the Industry

The future of DTF printing appears promising, with rapid advancements in technology poised to enhance its capabilities. As awareness grows about the benefits of DTF printing, many businesses are increasingly incorporating this technique into their production lines. Innovations in DTF printers, such as compact models suitable for small businesses, signify a shift towards making this technology more accessible to a broader audience, including hobbyists and emerging entrepreneurs.

Additionally, ongoing education and resource sharing within the DTF printing community continue to foster an environment of growth and innovation. The influx of online materials, tutorials, and user forums has made it easier for newcomers to familiarize themselves with best practices and troubleshoot challenges. As technology evolves and more users adopt DTF printing, the industry is likely to see even more groundbreaking applications in garment decoration, ensuring that this method remains relevant and sought after in various markets.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves several steps to transfer high-quality images onto fabric. First, artwork is printed on specialized PET film using eco-solvent inks. Next, a thermoplastic adhesive powder is applied to the wet ink and cured with heat. Finally, the film is heat pressed onto the fabric, activating the adhesive and ensuring a permanent bond. This method allows for intricate and colorful designs.

What are the benefits of DTF printing compared to other printing methods?

DTF printing offers numerous advantages, including high-quality prints with vibrant colors, versatility to work on a variety of fabrics, and durability against fading and peeling. It’s also cost-effective, requiring minimal setup and delivering quick production times. Additionally, DTF technology is often more eco-friendly, using water-based inks and sustainable materials.

What types of fabric can be used with DTF printing?

The DTF printing process is remarkably versatile and can be used on various fabric types, including cotton, polyester, and their blends. This flexibility makes it ideal for a wide range of applications, from custom apparel to promotional products, catering to diverse design needs.

What equipment is needed for DTF printing?

To start DTF printing, you’ll need high-quality DTF printers, pretreatment machines, heat presses, and suitable inks and adhesive powders. Investing in reliable DTF printing equipment is essential to achieving optimal print quality and efficiency in your printing endeavors.

How does DTF printing compare to sublimation printing?

While both DTF and sublimation printing produce vibrant and durable prints, the primary difference lies in their fabric compatibility. DTF can print on a broader range of materials, including cotton and blends, whereas sublimation is best suited for synthetic fabrics. DTF printing is gaining popularity for its versatility and ease of use.

Are there tutorials available for learning the DTF printing process?

Yes, there are many online resources, including videos and guides, dedicated to teaching the DTF printing process. These tutorials cover everything from understanding the technique to troubleshooting common issues, making it easier for beginners to familiarize themselves with DTF technology and enhance their printing skills.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A digital printing technology that uses heat transfer to apply high-quality images to fabrics. |

| The DTF Printing Process | Includes printing on film, applying adhesive, and heat transferring designs onto fabric. |

| Advantages of DTF Technology | Sharp designs, versatility on different fabrics, durable prints, cost-effective, and eco-friendly options. |

| Recent Developments | Growing demand and advancements, including compact printers and educational resources. |

| Getting Started with DTF | Research equipment, learn techniques, experiment with designs, and network with others. |

Summary

DTF Printing Process is revolutionizing how designs are transferred onto textiles, offering a seamless and efficient solution for garment decoration. This innovative printing technique allows for vivid and intricate designs directly printed on films, making it an ideal choice for both professional and amateur printers. With benefits such as high durability, versatility across various fabrics, and cost-effectiveness, DTF printing is quickly becoming the go-to method for those in the textile printing industry. As technology evolves, so do the opportunities for creativity and customization, ensuring that the DTF printing process continues to thrive and expand in popularity.