The DTF printer, or Direct-to-Film printer, is revolutionizing the world of textile printing with its cutting-edge technology that allows for vibrant, high-quality designs to be easily transferred onto various fabrics. As businesses and creatives increasingly turn to DTF printing technology for their customization needs, understanding how to choose a DTF printer tailored to your requirements becomes paramount. With key considerations such as print quality, speed, and user-friendliness, you can ensure your investment yields optimal results. In this guide, we will explore the best DTF printers on the market, examining expert reviews and essential features to help you make an informed decision. Join us as we delve into the dynamic landscape of DTF printing, where creativity meets technology.

Direct-to-Film (DTF) printing has emerged as a game-changer in the realm of custom textile design, offering a seamless way to transfer intricate graphics directly onto fabrics. As the industry shifts towards more innovative printing solutions, a high-performance Direct-to-Film printer is a savvy choice for artists and businesses alike. Choosing the right model involves a thorough understanding of DTF printer reviews that highlight performance metrics and user experiences. Factors like ease of use and print durability play a crucial role in ensuring that your selected device not only meets but exceeds your productivity goals. This comprehensive guide aims to equip you with everything you need to know to navigate the diverse options of DTF printing technology.

Understanding DTF Printing Technology

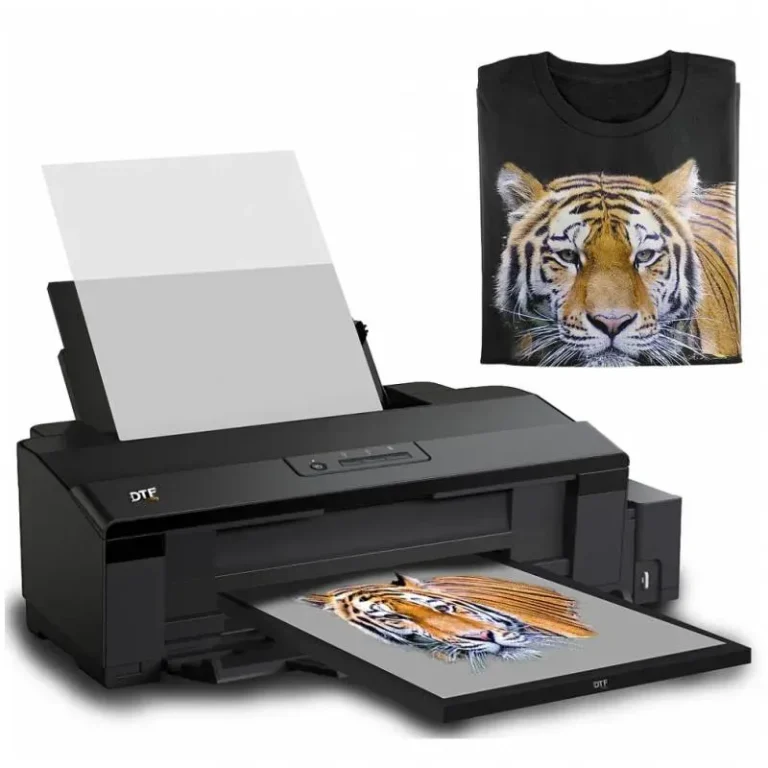

Direct-to-Film (DTF) printing technology simplifies the process of creating vibrant, full-color designs for textiles by eliminating several steps required in traditional printing methods. By using a specialized ink, DTF printers print directly onto a film, which is then transferred onto fabrics using heat and pressure. This method has gained momentum due to its versatility in handling different materials, from cotton to synthetic fabrics, allowing designers and businesses to produce high-quality prints with ease.

The potential of DTF printing technology also lies in its durability and adaptability. Unlike traditional methods, DTF prints boast superior wash resistance and remarkable flexibility, making it suitable for a wide range of applications, including apparel, home goods, and promotional items. This revolutionary printing method not only enhances the vibrancy of prints but also holds up against time and wear, ensuring that your projects maintain their appeal long after production.

Frequently Asked Questions

What is a DTF printer and how does it work?

A DTF printer, or Direct-to-Film printer, utilizes a unique printing technique that transfers printed designs onto fabric through a film intermediary. The printer prints designs using special inks on transfer film, which is then heat-pressed onto the fabric, allowing for vibrant, high-quality prints on various textiles.

How do I choose the best DTF printer for my needs?

To choose the best DTF printer, consider factors such as print quality (aim for at least 1200×1200 DPI), print speed for your workload, ease of use, and compatibility with materials. Additionally, evaluate the cost of consumables, the printer’s durability, and the level of manufacturer support to ensure smooth operations.

What are the top features to look for in DTF printing technology?

Key features in DTF printing technology to consider include high print resolution, fast production speeds, user-friendly operation, low maintenance requirements, and the ability to work with various fabric types. It’s also beneficial to look for printers that offer eco-friendly inks and materials.

Where can I find DTF printer reviews to make an informed decision?

DTF printer reviews can be found on various online platforms, including dedicated printing forums, industry blogs, and review websites. It’s advisable to check customer feedback on the specific models you’re considering to gather real-world experiences and insights.

What are the common costs associated with maintaining a DTF printer?

Common costs associated with maintaining a DTF printer include the price of inks, transfer films, cleaning supplies, and occasional repairs. Evaluating these ongoing expenses is crucial as they can significantly add to the overall cost of ownership beyond the initial purchase price.

Can a DTF printer handle different fabric types?

Yes, one of the advantages of DTF printers is their versatility in printing on various fabric types, including cotton, polyester, and blends. This capability makes them an excellent choice for businesses seeking to produce high-quality designs on diverse textiles.

| Key Considerations | Description |

|---|---|

| Print Quality | Look for printers offering at least 1200×1200 DPI resolution for vibrant colors and sharp images. |

| Print Speed | Check specifications for hourly print output to meet productivity needs. |

| Ease of Use | Choose a printer with a user-friendly interface and compatible software. |

| Cost of Consumables | Consider ongoing costs of ink, transfer films, and maintenance. |

| Durability and Build Quality | Research customer reviews to find printers known for long-term reliability. |

| Manufacturer Support | Look for brands with solid warranties and responsive customer service. |

| Size and Footprint | Ensure adequate space in your workspace for the printer and materials. |

| Feedback and Reviews | Utilize customer feedback and expert reviews to gauge printer performance. |

Summary

DTF printers symbolize a transformative shift in printing technology, enabling both businesses and hobbyists to produce high-resolution prints with expressive colors and intricate designs. When selecting a DTF printer, it is vital to focus on print quality, speed, usability, and ongoing costs. By understanding these key factors, customers can ensure they choose a DTF printer that meets their unique requirements and facilitates their creative projects. This comprehensive approach will not only enhance productivity but also drive satisfaction in achieving superior printing results.