DTF gangsheet builder has emerged as a cornerstone for printers aiming to scale up without sacrificing quality, driving efficiency and enabling smarter automation across workflows. In the world of DTF, a gangsheet is a single sheet that carries multiple designs, and a dedicated builder arranges them for efficient layout. For teams tackling large print runs DTF, this tool maximizes sheet usage, reduces machine stops, and tightens cost control. By turning rough ideas into precise layouts, standardizing bleed and margins, and applying consistent color management, it accelerates prepress. Overall, adopting a robust gangsheet builder supports faster turnarounds, lower waste, and scalable output across garment and textile projects.

Viewed through an LSI perspective, this tool is a batch-layout optimizer for multi-design textiles, combining several graphics onto a single canvas. People may describe it as a prepress automation module that streamlines file prep, color setup, margins, and bleed for a unified sheet. Its value lies in consistency, reduced manual steps, and predictable ink usage across many items. In practice, production teams rely on template-based workflows, bulk spacing rules, and centralized color profiles to achieve repeatable results.

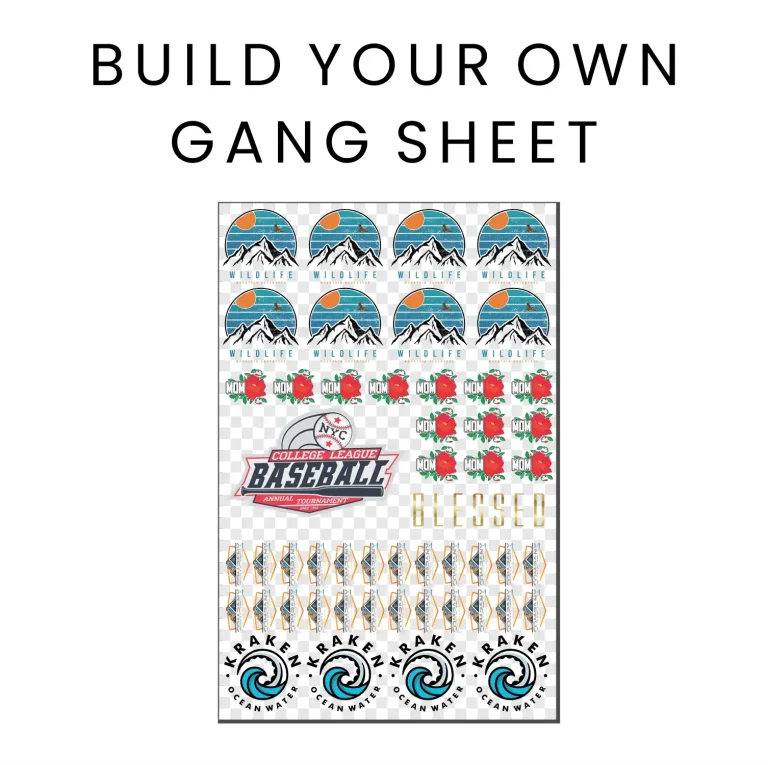

DTF gangsheet builder: Boosting DTF printing productivity for large runs

A DTF gangsheet builder is a purpose-built tool that enables printers to scale production without compromising image fidelity. It automates the arrangement of multiple designs on a single sheet, maximizing the use of every inch and minimizing unnecessary sheet changes. By coordinating placement, margins, and color management across all designs, this solution directly supports DTF printing productivity and helps shops push more output through the same equipment. The result is smoother prepress, faster transitions between orders, and a more predictable workflow for large volumes.

For teams handling large print runs, the framework provided by a DTF gangsheet builder translates rough concepts into production-ready layouts. This translates into shorter setup times, fewer manual tweaks, and tighter control over ink usage and transfer parameters. In short, the tool accelerates throughput while maintaining image fidelity, making it an essential component of a scalable DTF operation and a cornerstone for meeting aggressive schedules in high-demand environments.

DTF gangsheet: What it is and why it matters in gangsheet printing

A DTF gangsheet is a single sheet that carries multiple designs, organized with deliberate spacing, bleed, and margins to optimize transfer efficiency. In gangsheet printing, this approach reduces the number of separate prints and consolidates the workflow into a single pass, which can dramatically improve throughput and consistency across designs. By centralizing layout decisions, color management, and print areas, the gangsheet becomes a powerful vehicle for repeatable results.

In daily operations, a well-implemented gangsheet workflow minimizes prepress time and human error. Designers and operators define baseline parameters that govern all panels on the sheet, ensuring predictable results from run to run. When this process is paired with solid color management and template-driven layouts, the benefits ripple across production metrics like uptime, color fidelity, and overall efficiency in gangsheet printing.

DTF automation: Streamlining prep and layout for high-volume production

DTF automation acts as the backbone of a smooth, high-volume production line. When integrated with reliable RIP software and compatible printers, the gangsheet builder can automatically arrange files, apply color management, and estimate material usage per sheet. This not only reduces repetitive manual tasks but also creates a repeatable framework that operators can trust. The result is a sharper alignment between design intent and final output, with fewer opportunities for human error to creep into the process.

With automation handling the heavy lifting, teams experience tangible gains in throughput and reliability. The time saved on prep and layout translates into more productive printing minutes per shift, higher output per hour, and a lower risk of color drift across lots. In practice, DTF automation elevates overall DTF printing productivity by delivering consistent, repeatable results at scale.

Color fidelity and waste reduction for large print runs DTF

Maintaining color fidelity across dozens or hundreds of designs demands robust color management and precise control over ink performance. In large print runs DTF scenarios, centralized color management within the gangsheet workflow helps ensure that each panel prints with predictable hues while staying faithful to the original design. This consistency is essential for customer satisfaction and brand integrity, especially when multiple designs share the same sheet.

Efficient layout also plays a key role in reducing waste. By optimizing spacing, margins, and tiling, a well-configured gangsheet minimizes unused sheet areas and conserves media and ink over time. When color profiles are standardized across all panels, operators benefit from fewer reprints and reworks, further boosting DTF printing productivity during large-scale productions.

Integrating gangsheet builders with RIP software and printers for seamless workflows

Successful integration of a gangsheet builder requires compatibility with your RIP software and the broader printer fleet. A seamless workflow depends on clean file routing, consistent color profiles, and reliable transfer parameters across all devices. When the gangsheet tool communicates effectively with RIP software, it automates layout decisions while preserving the precise control needed for high-quality DTF outputs.

Beyond compatibility, practical considerations include design capacity, speed, and flexible layout rules. The best solutions let you define margins, bleed, and spacing per sheet or per project, while still enabling bulk automation. With robust integration, you gain predictable performance, easier template replication for large print runs DTF, and a more resilient end-to-end production line.

Best practices for gangsheet optimization in scalable production

To maximize gains from a gangsheet workflow, adopt practical best practices such as standardized design templates, safe margins, and consistent bleed guidelines. Grouping similar designs on a single sheet minimizes color changes and reduces ink-switch downtime on the printer. Standardized templates also simplify onboarding and ensure that new runs are production-ready from the start, which is crucial for scalable operations.

Other key practices include preflight checks for color profiles and file formats, clear color management baselines, and ongoing waste metrics reviews. Training operators and maintaining clear documentation for the gangsheet process help sustain high DTF printing productivity as order volumes grow. By combining templates, preflight discipline, and regular performance reviews, print shops can consistently hit targets in large-scale production.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it boost DTF printing productivity?

A DTF gangsheet builder is a software-driven tool that automatically arranges multiple designs on a single gang sheet, optimizing layout, margins, and color management. This streamlines prepress and setup, reduces machine stops, and directly improves DTF printing productivity and gangsheet printing efficiency.

How does DTF automation enhance gangsheet printing for large print runs?

DTF automation acts as a central hub that automatically arranges files, applies color management, and estimates material usage across gang sheets. This leads to more consistent output across large print runs and minimizes manual intervention in the DTF workflow.

What are the main benefits of using a DTF gangsheet builder during large print runs?

Key benefits include consistent color across designs, reduced setup time, optimized material usage, and improved workflow predictability. Together, these factors drive faster throughput and better cost control in DTF printing productivity for large print runs.

What should I consider when choosing a DTF gangsheet builder for high-volume operations?

Look for compatibility with your printers and RIP software, sufficient design capacity and speed, flexible layout rules, robust color fidelity controls, and the ability to save and reuse templates to support bulk automation in DTF gangsheet workflows.

What are best practices for gangsheet optimization in large print runs using a DTF gangsheet builder?

Standardize design templates with safe margins and bleed, preflight color profiles and file formats, optimize color management across the sheet, balance design density to avoid waste, and test with sample gang sheets before committing to a full run.

How does gangsheet optimization impact DTF automation and production throughput?

By coordinating spacing, margins, and color management on each sheet, a gangsheet builder minimizes misregistration and waste, enabling higher output per hour and more predictable delivery times as part of a comprehensive DTF automation strategy.

| Aspect | Highlights |

|---|---|

| What is a DTF gangsheet builder? |

|

| Benefits for large print runs |

|

| Productivity boost from smarter layouts |

|

| Practical workflow considerations |

|

| Automation role |

|

| Choosing a DTF gangsheet builder for large runs |

|

| Best practices for gangsheet optimization |

|

| Case for large print runs |

|

Summary

DTF gangsheet builder is transforming large-format textile production by enabling smarter layouts and automated workflows. In today’s competitive market, speed and consistency are the benchmarks of success in large print runs. By centralizing layout decisions and color management, a DTF gangsheet builder reduces prepress time, minimizes errors, and drives reliable throughput. For brands, designers, and print houses that manage frequent or large-scale orders, adopting a robust gangsheet-building workflow with a DTF gangsheet builder can deliver faster turnarounds, tighter cost control, and more predictable output, all while preserving image fidelity. When paired with compatible RIP software and printers, the DTF gangsheet builder becomes a strategic asset that scales production, reduces waste, and elevates overall DTF printing productivity.