UV Direct-to-Film technology is redefining how brands achieve bold, durable prints with rapid curing and UV curing innovations, versatile material compatibility, and fast turnaround times. In the realm of UV Direct-to-Film printing, designers can push vibrant colors on a wide array of fabrics while reducing post-processing and solvent usage. Direct-to-Film technology sits at the crossroads of transfer methods and UV-curing inks, delivering sharp details and broad color gamuts across textiles. Sustainable UV DTF solutions are strengthened by advances in film substrates, adhesives, and intelligent software that optimize color management and waste reduction, aligning with digital textile printing trends. As adoption grows, manufacturers can leverage these innovations for scalable, on-demand production, lower costs, and stronger sustainability credentials.

UV Direct-to-Film technology: The hybrid path to rapid, vibrant prints

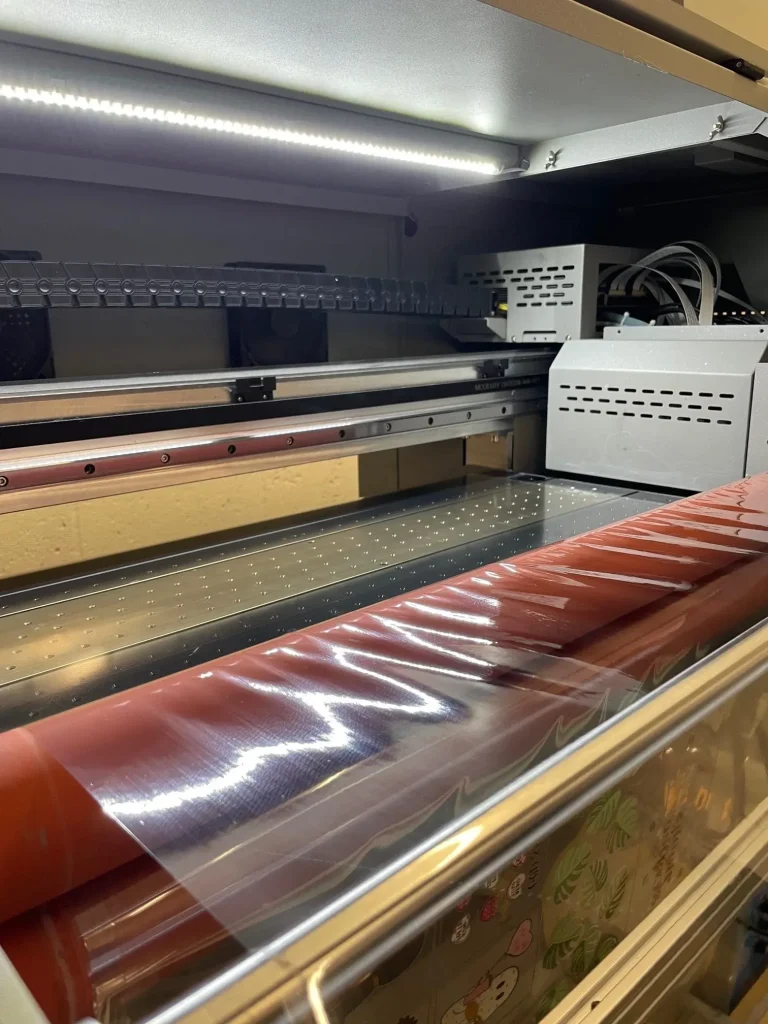

UV Direct-to-Film technology sits at the intersection of film-based transfer methods and modern UV-curing ink chemistry. In a typical UV DTF workflow, a digital printer lays down UV-curable inks onto a specialized carrier film, which is then heat-transferred onto a textile substrate. This combination enables high color fidelity, sharp edges, and rapid curing, aligning well with the needs of digital textile printing for on-demand and short runs.

The approach supports broader substrate compatibility and faster production cycles, helping brands meet tight deadlines without sacrificing image quality. By reducing post-processing steps and enabling immediate fixation through UV curing, UV Direct-to-Film technology positions print shops to deliver vibrant, durable results with lower turnaround times across a range of fabrics.

Direct-to-Film technology in practice: From design to garment

In practice, the Direct-to-Film technology workflow begins with printing the design onto a transparent film using UV-curable inks. The film is then aligned with the garment and heat-pressed to transfer the design. The UV curing step often occurs during or immediately after printing, ensuring fast fixation before the film is peeled away.

This integrated approach reduces solvent use and minimizes steps, making it ideal for short runs, customization, and rapid prototyping within the digital textile printing space. Operators gain predictable color reproduction on a variety of base fabrics, from light knits to darker substrates, thanks to optimized ink chemistries and film/adhesive formulations.

UV curing innovations driving speed and durability

UV curing innovations are central to speed and durability. LED-based cure systems deliver rapid, low-heat curing that protects heat-sensitive textiles while shortening processing times. Multi-angle curing and optimized lamp arrays help ensure uniform hardening across thick or dense fabrics, improving washfastness and edge integrity.

Advances in curing tech also influence maintenance costs and system uptime. Longer-lifetime lamps, reduced power draw, and smarter curing cycles translate into lower total cost of ownership. In tandem with Direct-to-Film printing, these UV curing innovations enable consistent results across runs and substrate types.

Sustainable UV DTF Solutions in modern textile printing

Sustainable UV DTF solutions emphasize waste reduction, energy efficiency, and responsible material choices. Digital workflows enable on-demand production, which minimizes overproduction and inventory waste. Recyclable or reusable film carriers and lower-emission adhesives contribute to a smaller environmental footprint in each print.

Designers and brands increasingly demand eco-friendly textiles, and UV DTF processes can align with that by lowering chemical usage and enabling shorter supply chains. When paired with optimized ink chemistries and durable prints, sustainable UV DTF solutions support longevity and recyclability across product life cycles.

Digital textile printing and the rise of UV Direct-to-Film integration

As part of the digital textile printing landscape, UV Direct-to-Film plays a complementary role alongside dye-sublimation and direct-to-garment methods. For small runs, personalization, and rapid prototyping, UV DTF offers a cost-effective path to vibrant graphics on a wide range of fabrics. Its flexibility expands brand capabilities in fashion, sportswear, and home textiles.

Software advances, AI-assisted color matching, and automated finishing systems further integrate UV Direct-to-Film with broader digital textile workflows. The combined movement toward digitization and on-demand production makes UV Direct-to-Film a central pillar in modern print studios, enabling scalable customization with consistent color fidelity.

Adoption challenges and best practices for UV DTF

Adoption challenges revolve around substrate compatibility and process control. Some fabrics need pretreatment or primer to ensure optimal adhesion; registration accuracy matters on curved surfaces; long-term durability should be validated with wash tests. Supplier and shop training is necessary to optimize ink handling and film/adhesive choices.

Health and safety considerations around UV exposure, ink handling, and curing equipment require PPE, ventilation, and standard operating procedures. By conducting thorough testing across fabrics, establishing best practices, and monitoring performance, studios can mitigate risk while delivering consistent results in UV DTF environments.

Frequently Asked Questions

What is UV Direct-to-Film printing and how does Direct-to-Film technology work in practice?

UV Direct-to-Film printing uses UV-curable inks deposited on a carrier film via Direct-to-Film technology. The film is then heat-transferred to the textile with an adhesive layer, while UV curing fixes the design quickly. This workflow delivers sharp edges, a wide color gamut, and strong durability for fast turnarounds and versatile substrates.

How do UV curing innovations enhance performance in UV Direct-to-Film technology?

UV curing innovations, including LED-based cure systems and multi-angle curing, accelerate fixation, reduce heat exposure, and extend lamp life. These advances improve print durability on a range of fabrics and support higher production efficiency with consistent, rapid curing.

Why is UV Direct-to-Film printing considered a sustainable UV DTF solution for modern textiles?

UV Direct-to-Film printing can lower solvent use, reduce post-processing, and enable on-demand production, cutting waste and energy per print. Sustainable UV DTF solutions also focus on recyclable or reusable film carriers and eco-friendly adhesives to minimize environmental impact.

Which substrates, adhesives, and film choices maximize durability in UV Direct-to-Film technology?

Durability improves with optimized carrier films, adhesives, and substrate compatibility. Cotton, blends, and synthetics can be printed when paired with appropriate film formulations and primers or pretreatments, ensuring strong adhesion, clean release, and resilience to washing.

How does digital textile printing integrate with UV Direct-to-Film technology to enable on-demand production?

Digital textile printing complements UV Direct-to-Film by providing the design data, color management, and rapid prototyping needed for on-demand runs. AI-assisted color matching and robust RIP software help translate digital textile printing files into precise UV DTF transfers with consistent results.

What are common challenges when adopting Direct-to-Film technology and how can you optimize UV Direct-to-Film printing for color and durability?

Common challenges include substrate pretreatment, precise registration on curved surfaces, and validating washfastness. To optimize results, conduct substrate testing, calibrate printers and color management, ensure proper curing conditions, and follow safety guidelines for UV exposure and ink handling.

| Topic | Key Points |

|---|---|

| What UV Direct-to-Film technology is | Film-based transfer method using UV-curable inks that cure rapidly, delivering sharp edges, wide color gamuts, and durable prints on textiles with high color fidelity and resistance to cracking. |

| How it works (concept) | Printer deposits UV-curable inks onto a carrier film, then heat-transfers to fabric via adhesive; UV cure happens during/after printing for instant fixation. |

| Typical workflow | Direct-to-Film printing on carrier film → align with garment → heat transfer → UV curing → finished print; enables fast cycles and less post-processing. |

| Key innovations | – Inks and color management: broad color gamuts, opacity on white/light fabrics; durable adhesion. – Film substrates & adhesives: better release, stability, strong adhesion without gummy residues. – Printer/software integration: improved print-heads, RIP engines for crisp detail. – Substrate compatibility: supports athletic fabrics to fashion knits. |

| Speed and curing | Fast curing with LED options; shorter drying times; multi-angle or multi-pass curing for thicker prints; reduces energy use and maintenance. |

| Sustainability | Lower solvents and waste; on-demand production reduces inventory; recyclable/reusable film carriers and adhesives with lower environmental impact. |

| Applications | Fashion and activewear, home textiles, promotional items; suitable for small runs, personalization, and rapid prototyping. |

| Adoption challenges | Substrate pretreatment needs; registration accuracy; durability testing; health and safety around UV exposure and curing equipment; requires PPE and proper ventilation. |

| Industry trends | Complementary to broader digital textile printing; AI-assisted color management and automated finishing streamline workflows; supports on-demand customization and fast turnaround. |

| Future outlook | Automation, data-driven optimization, AI color matching, predictive maintenance; hybrid processes and multi-material designs; growing eco-friendly adoption. |

Summary

Conclusion: UV Direct-to-Film technology is a transformative driver in digital textile printing, marrying rapid UV curing with high-fidelity color reproduction across a wide range of fabrics. The technology supports fast production cycles, reduced solvents, and on-demand customization, aligning with sustainability goals and lean manufacturing. As ink chemistries, film substrates, and software continue to evolve, brands can achieve bolder graphics on more materials while maintaining durability and washfastness. The ongoing convergence with AI-driven color management and automated finishing points toward smarter, more efficient print studios, with UV DTF as a central pillar of future textile production.