DTF gangsheet builder workflow sets the stage for smarter design and faster production, placing the transfer process at the center of planning, color strategy, asset management, and garment execution across multi-style runs to maximize consistency from concept to customer, while aligning with the DTF printing workflow. This approach aligns artwork, color plans, and printed output for apparel, helping teams reduce errors, maximize material use, speed up approvals, and deliver consistent results across multiple styles, garment gang sheet considerations, and production shifts. By combining thoughtful design with efficient layout and robust color management, you can shorten feedback loops, streamline prepress, and scale your operations without compromising quality or color fidelity on the shop floor, in QC checks, or on final garments, and this also supports the DTF design workflow. In this guide, you’ll learn how to apply the system to create repeatable gangsheet templates, optimize sheet space with a grid system, and integrate color control into a broader apparel design workflow, aligned with DTF design and printing best practices. The result is a streamlined process that reduces waste, accelerates time to market, and supports consistent branding across garments by unifying design intent, production readiness, and post-press handling into a single, repeatable cycle, while enabling better team collaboration, clear handoffs between design and manufacturing, and easier onboarding for new crew.

In other words, the workflow focuses on batching several designs on a single transfer sheet to maximize space and reduce ink waste. Think of it as a structured pipeline that ties artwork preparation, color separation, and print-readiness into a single, repeatable routine. From a broader perspective, this approach aligns with related concepts like garment sheet planning, the apparel design workflow, digital proofing, and the use of gangsheet templates to standardize layouts. For teams, adopting this mindset means clearer handoffs between design and production, improved communication with printers and RIP software, and faster onboarding as templates and configurations become reusable. Together, these terms—transfer sheet optimization, multi-design layout, and color-stable printing—capture the same idea from different angles and help you communicate the value of a cohesive DTF design system.

DTF gangsheet builder workflow: a comprehensive framework for design, layout, and production

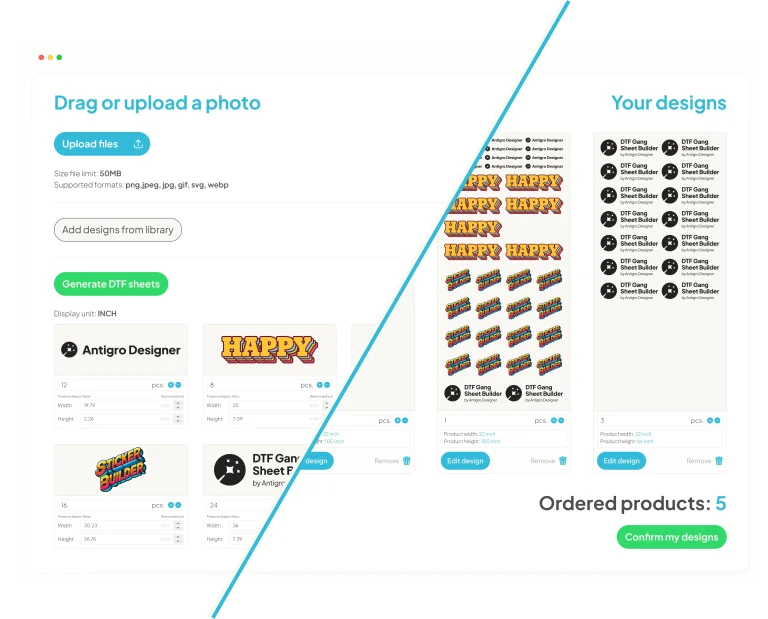

The DTF gangsheet builder workflow is a structured approach that unites artwork preparation, strategic layout, and print-readiness into one repeatable process. By bundling multiple designs onto a single transfer sheet, you optimize material usage, reduce handling time, and improve consistency across apparel runs. This framework naturally aligns with the broader DTF printing workflow and supports an efficient apparel design workflow from concept to final product.

In practice, this workflow emphasizes clear planning, precise grid layouts, and reliable file export formats so your printer and RIP interpret files consistently. Designers and production staff benefit from a shared methodology that minimizes misprints and misregistrations, while allowing teams to reuse proven gangsheet templates for faster onboarding and scalable production.

Maximizing fabric utilization through intelligent gang sheet layouts

Effective gang sheet layouts start with a well-defined grid, margins, and spacing that accommodate both the printer’s capabilities and the realities of garment production. By planning placement and scaling at the outset, you can fit more designs onto each sheet without compromising print quality or registration accuracy, which directly supports the DTF printing workflow.

Leveraging garment gang sheet principles helps you minimize waste and streamline trimming and application. Reusing gangsheet templates accelerates new projects, ensuring consistent margins and alignment across batches while tying back to the broader apparel design workflow for cohesive product lines.

Color management and separation within the DTF design workflow

Color management is central to reliable DTF transfers. The DTF design workflow guides how artwork is prepared, colors are separated, and how to preserve the intended look when printed on fabric. Establishing an appropriate palette and leveraging printer-specific color spaces minimizes surprises during production and ensures that designs reproduce faithfully.

A robust color-separation process balances artistic intent with print capabilities, avoiding overly delicate details that may not transfer well. By documenting color-critical elements and using appropriate color profiles, you create a predictable DTF printing workflow that aligns with client expectations and garment construction standards.

Using gangsheet templates to accelerate production and maintain consistency

Gangsheet templates provide a repeatable foundation for future projects. By saving proven layouts and margins as templates, designers can quickly assemble new designs on a gang sheet while preserving alignment and spacing, which speeds up the DTF design workflow and reduces human error.

Templates also support consistency across multiple garments and batches, reinforcing the garment gang sheet approach and keeping the broader apparel design workflow aligned with brand standards. Documented templates become a valuable resource for training, onboarding, and scalable production.

From artwork to print-ready files: a step-by-step DTF printing workflow

This stage translates concept into production-ready assets. Start with clean artwork, ensure proper color separations, and arrange multiple designs on a single gang sheet with consistent margins. Export the files with correct color profiles and appropriate formats to match your printer and RIP, ensuring a smooth DTF printing workflow.

A thorough pre-press check includes proofing, legibility, and alignment verification, followed by final adjustments before print. This step ties directly to the apparel design workflow, as feedback from proofs informs layout tweaks and color choices to maintain quality across garments.

Quality control, proofs, and post-press handling in apparel production

Quality control begins with digital or physical proofs to verify color accuracy, placement, and durability before full-scale production. Addressing issues early minimizes waste and ensures consistent results across batches, reinforcing a reliable DTF printing workflow.

Post-press handling—curing transfers, trimming, and verifying final placements on actual garments—completes the cycle. By following a disciplined post-press process, you preserve the integrity of the garment gang sheet plans and maintain alignment with the broader apparel design workflow and brand standards.

Frequently Asked Questions

What is the DTF gangsheet builder workflow and why does it matter in the DTF printing workflow?

The DTF gangsheet builder workflow is a structured method to create and arrange multiple designs on a single gang sheet for direct-to-film printing. It emphasizes planning, precise layout, color management, and reliable file export formats to optimize ink use and production time within the DTF printing workflow. By reusing gangsheet templates and aligning with the apparel design workflow, you improve efficiency and consistency across batches.

How does the DTF design workflow influence gangsheet layout decisions?

The DTF design workflow guides artwork preparation, color separations, and artwork conversion for transfer films. Those decisions feed directly into gang sheet layout, ensuring designs fit the grid, maintain color fidelity, and align with printer capabilities in the DTF printing workflow.

What is a garment gang sheet, and how does it fit into the DTF gangsheet builder workflow?

A garment gang sheet is a single sheet that carries multiple designs arranged for transfer to garments. In the DTF gangsheet builder workflow, you plan margins, spacing, and registration to maximize sheet usage and minimize misregistration, aligning with the garment gang sheet layouts and the broader apparel design workflow.

How can gangsheet templates speed projects in the DTF gangsheet builder workflow?

Gangsheet templates capture proven layouts and spacing, so you can reuse them for new designs. Using templates accelerates the DTF design workflow within the gangsheet builder workflow, reduces errors, and ensures consistent results across the DTF printing workflow and apparel design workflow.

What steps ensure print readiness and quality control in the DTF gangsheet builder workflow?

Steps include color management and separation, grid and margins, export with correct color profiles, and alignment marks. Perform proofs to verify placement and durability before production. This supports a reliable DTF printing workflow and aligns with the apparel design workflow.

How do you minimize waste and improve turnaround with the DTF gangsheet builder workflow?

Start with constraints, set up a grid, plan placement to maximize sheet usage, test on fabric swatches, and adjust before printing. Automate where possible and keep templates updated; this reduces waste and speeds production within the DTF printing workflow and apparel design workflow.

| Aspect | Key Points |

|---|---|

| Introduction | Design smarter starts with a clear and repeatable process. The DTF gangsheet builder workflow aligns artwork, color plans, and printed output for apparel, reducing errors, saving time, and enabling scalable production without sacrificing quality. This guide explains how to apply the workflow to streamline operations, maximize material usage, and deliver consistent results across garments. |

| What is the DTF gangsheet builder workflow? | A structured method for creating and arranging multiple designs on a single transfer sheet (gang sheet) for direct-to-film printing. It batches designs to optimize space, ink use, and production time, emphasizing planning, precise layout, color management, and reliable file export formats for your printer and RIP. |

| Benefits | More efficient color separations, better material utilization, faster production cycles, and easier quality control. When documented, designers can reuse successful gang sheet templates, accelerating new projects and supporting the broader apparel design workflow to reduce revisions and waste. |

| Key components | Artwork preparation and color management; Gang sheet layout and template use; File export and color separation; Print readiness and quality checks; Post-press handling and care. |

| How to build (Steps) | Step 1: Gather artwork and constraints. Step 2: Create a grid and plan placement. Step 3: Color management and separation. Step 4: Create print-ready files and verify specs. Step 5: Proof and pre-press validation. Step 6: Print, cure, and post-processing. |

| Practical tips | – Use reusable gang sheet templates to speed future projects and maintain consistency. – Prioritize color stability to reduce ink waste. – Maintain a color-critical workflow with proof checks. – Automate grid creation and export tasks to minimize errors. – Document the process with a simple SOP for consistency. |

| Common pitfalls | – Inconsistent margins or registration marks; – Overcomplicating color separations; – Ignoring fabric variability; – Poor file naming and organization. |

Summary

DTF gangsheet builder workflow is a practical, scalable approach to modern apparel production. By integrating artwork preparation, gang sheet layout, color management, and print readiness into a single repeatable process, you can deliver consistent, high-quality garments more quickly and with less waste. This approach also aligns with broader workflows like the DTF design workflow, garment gang sheet planning, and the overall apparel design workflow, ensuring design and production stay synchronized from concept to customer. With well-documented templates, careful color control, and efficient post-press handling, the DTF gangsheet builder workflow becomes a competitive advantage for apparel operations.