The DTF Gangsheet Builder is a cutting-edge innovation that is transforming the landscape of Direct to Film printing and revolutionizing printing productivity across various industries. This remarkable tool empowers businesses to produce multiple designs on a single sheet, significantly cutting costs and enhancing efficiency. As companies strive for cost-effective printing solutions, the DTF Gangsheet Builder emerges as an essential resource, helping to streamline workflows while maximizing output. By leveraging advanced textile printing technology, users can expect vibrant and high-quality prints that meet the evolving demands of the market. Embracing the DTF Gangsheet Builder not only ensures a competitive edge but also positions businesses to fully harness efficient printing methods in today’s fast-paced environment.

Introducing the DTF Gangsheet Builder—a robust solution designed for those seeking to elevate their printing operations with Direct-to-Film technology. This remarkable tool facilitates the simultaneous printing of various designs on one sheet, streamlining the entire production process. For businesses focusing on cost-efficient printing strategies, the Gangsheet Builder helps minimize waste while maximizing output, presenting an ideal choice for modern textile production. By utilizing this innovative approach to printing, companies can significantly improve their overall productivity and responsiveness to customer demands. In a world where effective and efficient printing solutions are paramount, the DTF Gangsheet Builder stands out as a game-changing option for businesses of all sizes.

Understanding DTF Gangsheet Technology

The DTF (Direct to Film) Gangsheet technology revolutionizes the way businesses approach garment printing by enabling the combination of multiple designs onto a single sheet. This means that printing operations can leverage resources more efficiently, reducing both material waste and the associated costs of printing. Through this method, companies can execute complex and colorful designs that appeal to a broad audience, ensuring they stay competitive in a constantly evolving market.

Utilizing the DTF Gangsheet Builder facilitates easier management of print productions, allowing businesses, whether they are small startups or established firms, to implement high-quality printing with less time investment. This innovative solution not only enhances the printing process but also allows for a greater exploration of creative options. By mastering this technology, businesses can differentiate their offerings in a saturated textile market.

Cost-Effective Printing Solutions with DTF

Cost efficiency is one of the primary benefits of integrating DTF Gangsheet technology into your operations. By amalgamating several designs onto a single film sheet, businesses can lower their printing costs significantly. This method reduces waste not only of the film used but also of ink and other materials, leading to tangible savings that can be redirected towards business growth or marketing efforts.

Additionally, companies leveraging DTF printing can adapt more swiftly to market demands and client preferences without incurring substantial additional costs. This cost-effective approach is particularly advantageous for small and medium-sized enterprises, enabling them to operate sustainably while maintaining profitability, crucial for long-term success.

Boosting Printing Productivity

In today’s fast-paced market, printing productivity is a key driver of business success. With the DTF Gangsheet Builder, companies enjoy accelerated production times due to the ability to print multiple designs in one pass. This advancement not only enhances throughput but also caters to the growing customer expectation for quick turnaround times, which is essential for maintaining a competitive edge.

By streamlining the printing process, businesses can easily increase their order capacity. This increased productivity can lead to enhanced customer satisfaction, as businesses are better equipped to meet the rising demand while maintaining high standards of quality—resulting in repeat business and customer loyalty.

The Versatility of DTF Gangsheet Printing

The versatility offered by DTF Gangsheet printing technology is unmatched in the textile printing industry. The ability to print on various fabrics, from delicate cotton to robust polyester, opens up a realm of possibilities for businesses. This flexibility allows companies to service a diverse clientele, catering to different garment needs while ensuring high-quality output.

Moreover, DTF printing is known for its ability to produce vibrant, lasting colors that resonate well with consumers. The combination of quality and versatility positions businesses leveraging the DTF Gangsheet Builder favorably in their market, enabling them to create garments that not only meet customer tastes but also withstand the test of time.

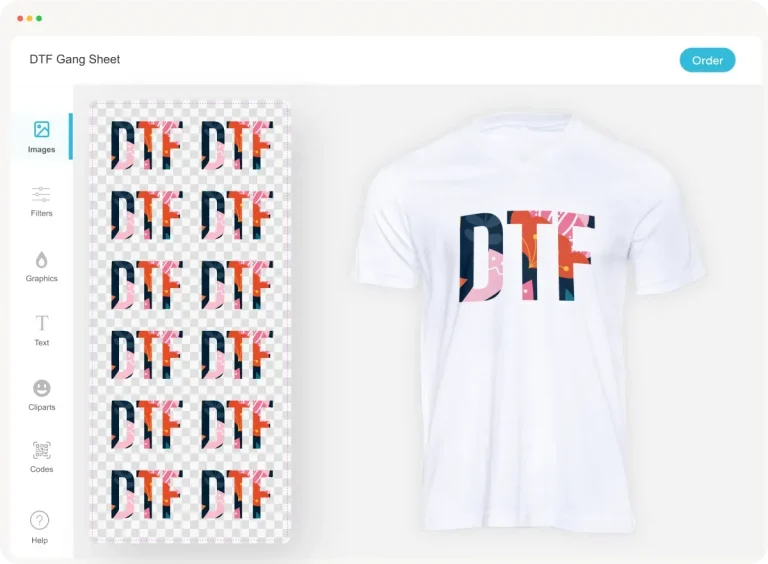

User-Friendly Software for Efficient Design

One of the highlights of the DTF Gangsheet Builder is its user-friendly software that simplifies the design process for users at all skill levels. This feature empowers business owners and their teams to navigate the complex task of garment printing without needing extensive graphic design training, thereby democratizing access to high-quality printing capabilities.

By eliminating the barriers to entry in design creation, businesses can focus on developing innovative and eye-catching products swiftly. This accessibility not only enhances workflow efficiency but also encourages creativity within teams, fostering an environment where new ideas can flourish and leading to exciting, market-driven garment offerings.

Future Considerations in DTF Technology Development

As the textile printing industry progresses, ongoing developments in DTF technology promise to enhance productivity and efficiency further. Businesses that systematically adopt and integrate these changes stand to benefit significantly from improvements in equipment speed, print quality, and cost management. Keeping abreast of these trends is vital for maintaining a competitive edge.

Emerging businesses and established firms alike must explore the synergy between traditional printing methods and DTF technology. Embracing these innovations not only prepares companies for present challenges but also positions them well for future growth and success in an ever-changing market landscape.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance printing productivity?

The DTF Gangsheet Builder is a cutting-edge tool in Direct to Film printing that allows businesses to print multiple designs on a single sheet, significantly improving printing productivity. By streamlining workflows, it enables faster turnaround times, allowing companies to meet customer demands efficiently.

How does the DTF Gangsheet Builder provide cost-effective printing solutions?

The DTF Gangsheet Builder delivers cost-effective printing solutions by minimizing material waste through its ability to print several designs at once. This reduces the cost per print, making it especially beneficial for small to medium-sized enterprises looking to optimize their printing operations.

What are the advantages of using the DTF Gangsheet Builder in textile printing technology?

Utilizing the DTF Gangsheet Builder in textile printing technology offers several advantages, including high-quality, vibrant prints on various fabrics. This versatility allows businesses to adapt to different garment demands, catering to both soft and heavy materials without compromising on quality.

Is the DTF Gangsheet Builder user-friendly for those without graphic design experience?

Yes, the DTF Gangsheet Builder features intuitive software that makes it user-friendly for individuals without extensive graphic design experience. This accessibility empowers startups and small businesses to create striking designs confidently without the need for advanced training.

Can the DTF Gangsheet Builder help reduce labor costs in printing operations?

Absolutely! The DTF Gangsheet Builder can significantly reduce labor costs by automating the gangsheet process, which traditionally required extensive manual preparation. This allows employees to focus on strategic tasks, enhancing overall productivity and fostering a more innovative work environment.

What recent developments have emerged in DTF technology regarding the Gangsheet Builder?

As of 2023, recent developments in DTF technology indicate growing interest in the DTF Gangsheet Builder among startups and established businesses alike. Companies are increasingly recognizing its potential to blend traditional printing methods with innovative DTF technology, shaping the future of textile printing for enhanced efficiency and productivity.

| Key Benefits | Description |

|---|---|

| Cost Efficiency | Minimizes material waste and reduces the cost per print, crucial for small to medium-sized enterprises. |

| Increased Productivity | Enables faster turnaround times by allowing multiple designs on one sheet, enhancing order capacity and customer satisfaction. |

| Quality and Versatility | Offers vibrant colors and robust prints across various fabrics, meeting high consumer expectations for quality. |

| User-Friendly Software | Intuitive design software that requires no extensive graphic design experience, making it accessible for new businesses. |

| Reduced Labor Costs | Automates printing processes, freeing staff for strategic tasks and enhancing overall productivity. |

Summary

DTF Gangsheet Builder is a groundbreaking innovation for businesses engaging in printing and garment production. This tool enhances cost efficiency by allowing multiple designs to be printed on one sheet, which helps in minimizing waste and reducing expenses. Moreover, the DTF Gangsheet Builder promotes increased productivity and faster turnaround times, essential for meeting customer demands. Its user-friendly software empowers businesses, regardless of size, to create high-quality prints on various fabrics, ensuring versatility and satisfaction. By adopting the DTF Gangsheet Builder, businesses can not only elevate their operational efficiency but also secure a competitive advantage in the evolving garment printing landscape.