DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel market by simplifying the process of creating stunning designs on various fabrics. This innovative printing technology allows artists and businesses alike to produce vibrant graphics that can be applied to garments with remarkable precision and ease. With DTF printing, the possibilities for personalized apparel are virtually endless; from t-shirts to tote bags, this method accommodates a diverse range of items. In this blog, we will delve into how to create designs using the DTF transfer process, explore engaging apparel design techniques, and uncover the myriad benefits of DTF printing for custom clothing. Join us as we uncover the secrets behind this cutting-edge technology that is shaping the future of fashion.

The world of customizable clothing is embracing a new wave of innovation with Direct-to-Film technology, often referred to as DTF printing. This modern method offers an efficient avenue for printing detailed and colorful imagery directly onto transfer film, which can then be heat-pressed onto various types of fabric. As more individuals and businesses seek unique ways to express their brand or personal style, understanding the DTF transfer process has become essential. Beyond simple t-shirt printing, this technique enables a multitude of creative applications, catering to a growing demand for quality and versatility in apparel design. Let’s explore these transformative processes and discover how anyone can harness this technology to enhance their clothing creations.

The Evolution of DTF Printing in Custom Apparel

Direct-to-Film (DTF) printing has reshaped the landscape of custom apparel over the last few years. This innovative technology allows for vibrant, detailed prints that adhere seamlessly to various fabrics, making it a game-changer for designers and apparel manufacturers. The evolution of DTF printing has not only made the process more accessible but has also elevated the quality of custom apparel options available in the market today.

With traditional printing methods often limited by design complexity and color vibrancy, DTF transfers emerge as a versatile solution. They enable designers to produce intricate graphics and lively colors that enhance the appeal of custom apparel, appealing to both small businesses and individual creators looking to stand out in a crowded market.

Key Benefits of Utilizing DTF Transfers

DTF transfers offer several advantages that make them an attractive option for custom apparel enthusiasts. Firstly, the technology allows for high-resolution prints, capturing fine details that many other methods, such as screen printing, struggle to replicate. This superior detail ensures that designs come out exactly as envisioned, providing a professional finish that attracts customers.

Moreover, DTF printing boasts versatility regarding material compatibility. It can effectively transfer designs onto a wide range of fabrics—from cotton and polyester to blends—creating endless possibilities for custom apparel. This broad applicability means businesses can diversify their offerings without investing in different printing technologies.

Essential Equipment for Effective DTF Printing

To embark on the DTF printing journey, it is crucial to invest in specific equipment tailored for this technique. A DTF printer is essential, as it utilizes special inks designed to bond effectively with hot melt adhesive powders. Choosing the right printer is vital, as it directly impacts the quality of the output, ensuring every detail of the design is printed with clarity.

In addition to a DTF printer, a reliable heat press machine is also necessary. This tool applies consistent heat and pressure, which are critical for successfully transferring designs onto fabrics. Combining these pieces of equipment with high-quality materials sets the foundation for creating stunning custom apparel that meets both personal and commercial needs.

Steps to Create Stunning DTF Designs

Creating unique designs using DTF transfers involves a series of well-defined steps that are crucial for achieving stunning results. The journey begins with the design creation phase, where graphic design software plays an integral role. Here, designers can unleash their creativity by crafting original artworks or modifying existing images to fit their apparel visions.

Once the design is finalized, the next step is to print it onto the specialized transfer film. Precision in this phase is crucial, as the printed quality will affect the final product. Following the printing phase, applying the hot melt adhesive powder and curing it with heat is essential to ensure durability and adherence to the fabric during the heat pressing process.

Understanding the DTF Transfer Process

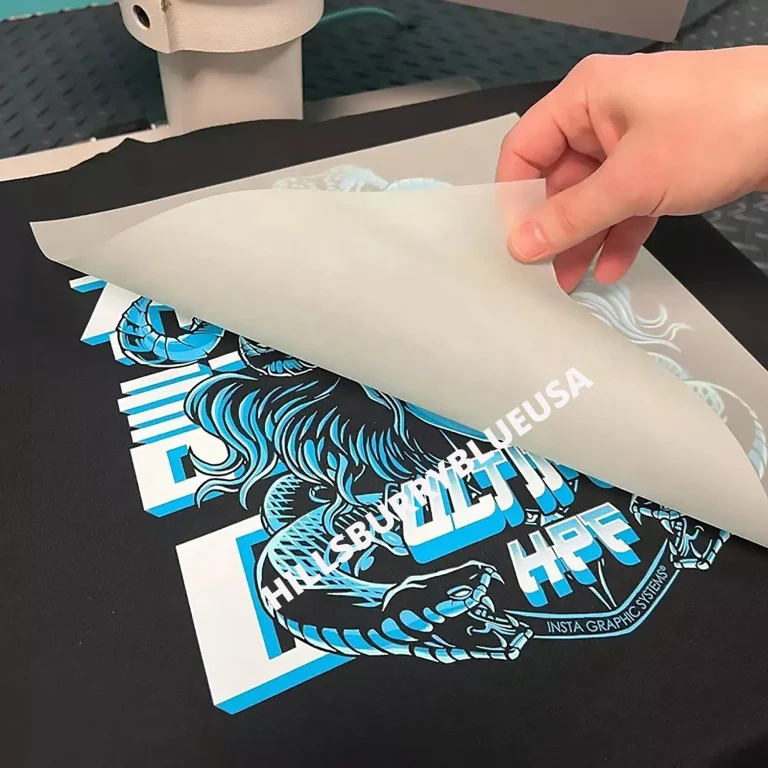

The DTF transfer process is a fascinating blend of technology and artistry, allowing for the transformation of intricate designs into wearable masterpieces. It begins with high-quality printing onto a transfer film, where attention to detail is paramount. This film is then coated with a hot melt adhesive powder that guarantees the design will stay intact and vibrant once pressed onto the garment.

After the adhesive is cured, the process culminates with heat pressing the design onto the intended fabric. This step is key to ensuring that the transfer bonds securely with the material. Understanding each step is vital for anyone looking to delve into DTF printing, as any minor oversight can impact the quality of the finished custom apparel.

Exploring Market Trends in Custom Apparel Printing

The world of custom apparel printing is constantly evolving, particularly with DTF technology gaining popularity. Recently, the industry has seen notable trends such as a shift towards sustainability, with eco-friendly inks and materials becoming a priority for consumers and manufacturers alike. This trend not only reflects growing environmental awareness but also opens up opportunities for businesses to attract eco-conscious customers.

Additionally, advancements in DTF printing equipment, such as faster print speeds and enhanced efficiency, have contributed to the growth of this niche. Custom apparel businesses are leveraging these innovations to maximize productivity and reduce overhead costs, allowing them to serve a broader clientele while maintaining quality. Staying ahead of these trends is essential for anyone involved in custom apparel to remain competitive in this dynamic field.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a cutting-edge method for producing custom apparel designs. It works by printing your artwork onto a special transfer film, adding a hot melt adhesive powder, and then using a heat press to transfer the design onto fabric. This process creates vibrant, detailed graphics suitable for a variety of materials.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers provide numerous advantages, including superior detail and color vibrancy, compatibility with various fabric types like cotton and polyester, and cost-effective production for both small runs and one-offs. These features make DTF printing a favored choice among custom apparel creators.

What equipment do I need for DTF transfers?

To create DTF transfers, you’ll need a DTF printer capable of using specialized inks, hot melt adhesive powder for adhesion, and a heat press machine to apply heat and pressure during the transfer process. Having these tools is essential for achieving high-quality custom apparel designs.

How can I create unique designs using DTF printing?

Creating unique designs with DTF printing involves several key steps: first, use graphic design software to create or modify your artwork. Then, print it onto the DTF transfer film, apply the hot melt adhesive powder, cure it with heat, and finally, use a heat press to transfer the design onto your chosen garment.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and various blends. This versatility ensures that DTF printing is suitable for a diverse assortment of custom apparel items, from t-shirts and hoodies to bags and hats.

What are the current trends in DTF printing technology?

Current trends in DTF printing technology include increased speed and efficiency with advancements in printer models, the use of eco-friendly inks that minimize environmental impact, and integrated systems that streamline the DTF transfer process. These innovations enhance workflow and product quality for custom apparel makers.

| Key Point | Details |

|---|---|

| Introduction | DTF printing technology transforms custom apparel by enabling high-quality prints on various materials. |

| What Is DTF Printing? | A multi-step process involving printing on a special film, applying adhesive, and heat pressing onto garments. |

| Advantages | 1. Superior detail and color; 2. Versatile material compatibility; 3. Cost-effective for small runs. |

| Equipment Needed | DTF printer, hot melt adhesive powder, and a heat press machine are essential. |

| Steps to Create Designs | 1. Design creation; 2. Printing; 3. Applying adhesive powder; 4. Heat pressing. |

| Market Trends | Increased printer efficiency, eco-friendly inks, and integrated systems are emerging trends. |

Summary

DTF Transfers are at the forefront of custom apparel creation, offering designers and businesses a revolutionary way to produce stunning garment prints with ease and precision. This innovative printing technique leverages specialized films and heat transfer methods to create vibrant, detailed designs that can adhere to a wide variety of fabrics. As a result, small businesses and independent creators can seamlessly bring their artistic visions to life, while also benefiting from the cost-effectiveness and versatility that DTF transfers provide. With advancements in printing technology and an increasing emphasis on sustainability, the DTF printing process is not only improving in efficiency but also aligning with eco-friendly practices. As you explore the possibilities provided by DTF transfers, you can elevate your custom apparel offerings and stay competitive in today’s dynamic market.