DTF transfers, or Direct to Film printing, are setting a new benchmark in the T-shirt printing industry by delivering exceptional quality and versatility. This innovative technology allows for strikingly vibrant designs to be printed directly onto a specialized film before being transferred onto apparel, significantly enhancing the capabilities of custom apparel production. As the demand for unique and personalized T-shirts surges, businesses are turning to DTF printing for its ability to quickly and affordably produce high-quality garments. With key players like Sam’s DTF Transfers leading the charge, the adoption of DTF technology is revolutionizing traditional garment printing methods. In this article, we’ll delve into how DTF transfers are reshaping the industry landscape and driving apparel printing innovations.

Revolutionary advancements in T-shirt printing technology, such as Direct to Film (DTF) transfers, are transforming how businesses approach custom designs and production. This cutting-edge method utilizes a unique film medium, allowing for exceptional detail and vibrant color application that was not possible with older printing techniques. As more apparel producers explore efficient solutions for on-demand printing, DTF printing is gaining momentum across various markets. The fast production times and cost-effectiveness of DTF technology enable both large-scale manufacturers and small startups to thrive in a competitive landscape. Ultimately, these apparel printing innovations promise a bright future for custom apparel enthusiasts.

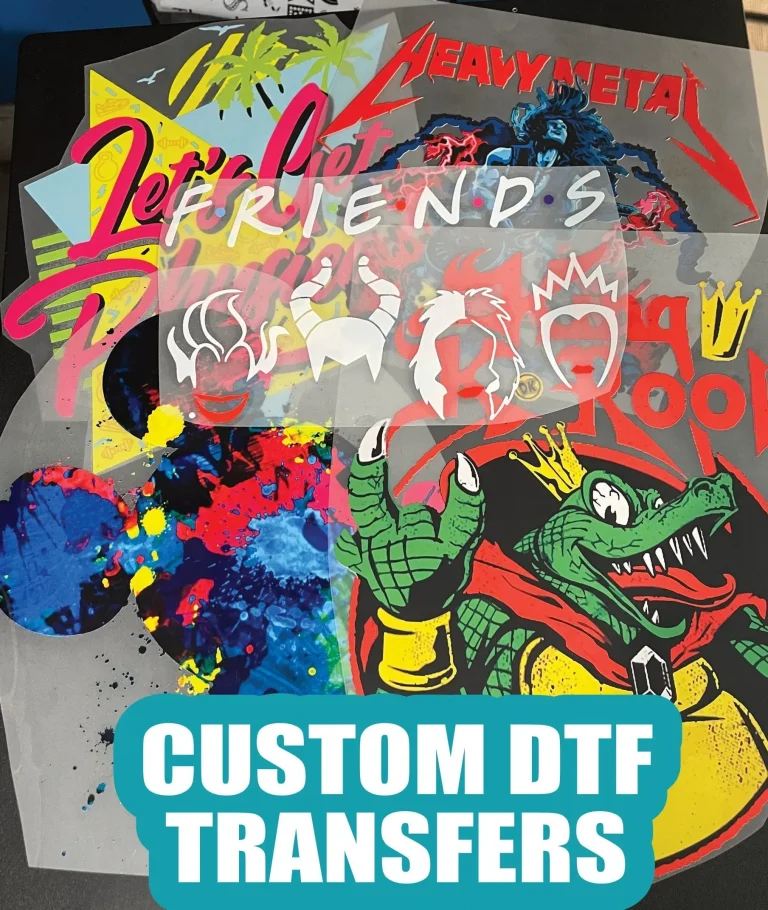

Understanding DTF Transfers: The Future of Custom Apparel

Direct to Film (DTF) transfers have uniquely positioned themselves as a game-changer in the custom apparel market. This innovative printing technology allows for vibrant, high-quality graphics to be printed on special film, rather than on fabric, ensuring exceptional detail and color vibrancy that traditional methods struggle to achieve. As consumers become more discerning and seek out personalized apparel options, DTF printing offers an efficient solution that caters to both large-scale operations and independent designers. It empowers brands to embrace creativity without the constraints associated with conventional printing methods.

Moreover, the versatility of DTF printing technology means it can accommodate a wide variety of materials—from cotton to polyester and their blends—perfect for the diverse range of garments and products that brands wish to offer. With lower setup costs and the flexibility of printing on demand, businesses can respond quickly to market trends, significantly reducing lead times while offering customers exactly what they desire in terms of unique designs and products.

Advantages of DTF Printing Technology in T-Shirt Production

DTF printing technology stands out in T-shirt production due to its remarkable cost-effectiveness, especially for small businesses and startups. Unlike traditional methods such as screen printing, which often require large minimum orders and extensive setup processes, DTF allows companies to start with small quantities and grow their production as demand increases. This flexibility helps entrepreneurs test the market with customized designs without the fear of overproduction, making it an ideal choice for those looking to carve out a niche in the competitive apparel landscape.

Additionally, DTF transfers significantly reduce production times while maintaining high-quality outputs. Thanks to advancements in DTF technology, businesses can now produce intricate designs in record time, enabling them to fulfill orders rapidly and keep pace with consumer demand. With companies like Sam’s DTF Transfers leading the way, it’s evident that DTF printing is not just about high-quality prints but also about creating efficient, streamlined processes that support the fluidity required in today’s fast-moving market.

Leading Innovators in DTF Transfers: Sam’s DTF Transfers and Insta Graphic Systems

Sam’s DTF Transfers exemplifies how a commitment to quality and service can distinguish a business in the competitive custom apparel market. By focusing on in-house printing, they ensure immediate availability of DTF transfers, allowing customers to combine speed with premium quality. This approach helps fulfill the growing demand from both small online brands and larger retailers seeking innovative solutions to meet consumer expectations for unique, custom designs. As the landscape of T-shirt printing evolves, Sam’s DTF Transfers remains a pivotal player by prioritizing customer satisfaction and embracing the technological advantages provided by DTF printing.

Similarly, Insta Graphic Systems has made significant strides by introducing advanced DTF heat transfer products designed for durability and extraordinary print quality. Their innovations reflect the technological prowess that is essential for elevating the standards within the T-shirt printing industry. By continuously pushing the boundaries of what can be achieved with DTF technology, they enable brands to offer colorful, long-lasting images that resonate with end consumers, reinforcing the value of investing in advanced printing solutions.

Global Trends in DTF Printing Technology and Custom Apparel

The global interest in DTF printing technology is indicative of its potential to reshape custom apparel production worldwide. For instance, companies like AM.CO.ZA in South Africa have introduced compact A3 DTF printers tailored for the growing print-on-demand market. These advancements cater specifically to the needs of emerging businesses that require efficient, small-batch printing solutions that traditional methods cannot easily provide. The response from the market signifies a unified global acceptance of DTF technology, setting the stage for its expansion beyond predominantly Western markets.

As DTF technology continues to gain traction worldwide, it opens doors not only for established businesses but also for new entrants in the custom printing field. The ability to easily and affordably produce customized apparel means that entrepreneurs from various backgrounds can enter the market without the burdensome investments associated with traditional printing methods. This democratization of T-shirt printing is essential for fostering innovation and competition in the global landscape, making DTF a foundation for future growth in custom apparel.

Future Projections: The Expansion of DTF Transfers in the Apparel Sector

Looking ahead, the future of DTF transfers in T-shirt printing appears promising, with expectations of widespread adoption and continuous innovation. As DTF technology becomes more accessible and affordable, we will likely see an increase in its usage among established brands and startups alike. The ability to personalize offerings while maintaining high standards of quality is a critical factor that will drive growth in this sector. Businesses that leverage DTF printing capabilities can position themselves to attract new customers eager for customized apparel options in an increasingly competitive marketplace.

Furthermore, with industry leaders like Sam’s DTF Transfers and Insta Graphic Systems at the forefront of this shift, we can anticipate ongoing advancements that refine the printing process, improve materials, and enhance overall production techniques. Such innovations will empower brands to stay ahead of customer trends and expectations, thus redefining the standards in custom apparel production. As the technology matures, the barriers to entry for new players will further diminish, ultimately fostering a creativity-driven market where any brand can make a significant impact.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel production?

DTF Transfers, or Direct to Film transfers, are a modern printing technology that allows high-quality images to be printed onto a special film and then transferred to fabric through heat and pressure. This process creates vibrant designs perfect for custom apparel, including T-shirts, by allowing for easy application on various material types.

What are the advantages of using DTF printing technology for T-shirt printing?

DTF printing technology offers numerous advantages, including high-quality and vibrant prints, rapid production times, and cost-effective solutions for producing custom apparel. These benefits make DTF the preferred choice for businesses looking to fulfill personalized design requests with minimal setup and overhead costs.

How does DTF Transfers impact the turnaround time for T-shirt orders?

DTF Transfers significantly reduce turnaround times in T-shirt orders because the process requires less setup compared to traditional methods like screen printing. This efficiency allows businesses, such as Sam’s DTF Transfers, to offer quick service and cater to urgent customer demands in the custom apparel market.

Can DTF Transfers be used on various fabric types for custom apparel?

Yes, DTF Transfers are versatile and can be used on a wide range of fabric types, including cotton, polyester, and fabric blends. This flexibility allows businesses to diversify their custom apparel offerings and meet the specific needs of their customers.

What role do companies like Sam’s DTF Transfers play in the DTF printing industry?

Companies like Sam’s DTF Transfers are pivotal to the DTF printing industry by providing high-quality transfer services with no minimum order requirements. Their in-house capabilities and commitment to innovation enable even small businesses to utilize DTF technology effectively, fostering growth and creativity in custom apparel production.

What global trends are shaping the future of DTF printing technology?

DTF printing technology is gaining global traction as businesses around the world adopt it for their custom apparel needs. Innovations like compact A3 DTF printers in markets such as South Africa demonstrate the demand for efficient, smaller batch production solutions, suggesting a strong international interest in the advancements of DTF printing.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF (Direct to Film) transfers allow for printing on a special film that is then transferred to the fabric using heat and pressure, resulting in durable, vibrant prints. |

| High-Quality Prints | Produces vibrantly detailed images, allowing versatility on various fabrics and minimizing setup time compared to traditional methods. |

| Rapid Production Times | Shorter turnaround times help brands respond to market demands quickly, enhancing custom design offerings. |

| Cost-Effective Solutions | Ideal for small businesses, allowing production of small batches while minimizing waste. |

| Leading Innovators | Sam’s DTF Transfers and Insta Graphic Systems are key players driving innovation and quality in the DTF printing market. |

| Global Trends | Growing international interest in DTF technology, with new innovations emerging to meet print-on-demand needs. |

| Future of DTF Transfers | Continued advancements will likely make high-quality printing more accessible, benefiting both established and new businesses. |

Summary

DTF Transfers are revolutionizing the T-shirt business by introducing high-quality, cost-effective, and rapid production solutions for custom apparel. This innovative technology allows businesses of all sizes to produce vibrant designs efficiently while minimizing operational costs. As industry leaders like Sam’s DTF Transfers and Insta Graphic Systems innovate continuously, the future of custom printing looks brighter, promoting broader accessibility and excellence in apparel production.