In recent years, DTF transfers, also known as Direct to Film transfers, have drastically revolutionized the world of custom apparel printing. This innovative printing technique allows designers and businesses to efficiently apply vibrant and detailed graphics onto a wide array of fabrics with remarkable precision and durability. Unlike traditional printing techniques, the DTF transfer process ensures high-quality results, making it easier to create bespoke clothing items that capture the essence of any design. For those looking to elevate their printing capabilities or dive into a new venture, understanding DTF printing and its applications is essential. This guide will explore everything you need to know about DTF transfers, from the intricate processes involved to the latest market trends.

Direct to Film printing, often abbreviated as DTF, is emerging as a cutting-edge solution for numerous businesses venturing into custom apparel printing. This method involves transferring detailed designs onto specialized transfer film, which subsequently adheres to various fabric types using heat application. The uniqueness of this process lies in its ability to handle complex color schemes and intricate patterns that are often challenging with conventional printing methods. As demand for personalized clothing continues to surge, many are turning to DTF transfers for their reliability and versatility. This article delves into the essentials of the DTF transfer process, showcasing why it is becoming a preferred choice for both small businesses and established brands.

The Basics of DTF Transfers: A Comprehensive Overview

DTF transfers, or Direct to Film transfers, offer a unique approach to printing on textiles by utilizing a film medium that effectively captures high-resolution graphics. This technique stands out in the printing realm as it combines vibrancy with ease of use. DTF printing eliminates the need for complex setups typically associated with screen printing, making it an ideal solution for small businesses and independent creators looking to provide custom apparel quickly. Furthermore, the simplicity of the DTF transfer process empowers even novices in the printing industry to achieve professional results without extensive training.

The main appeal of DTF transfers lies in their versatility and compatibility with various fabric types, like cotton and blends. Whether it’s a colorful design for a summer promotional T-shirt or detailed artwork on a hoodie, DTF technology showcases incredible adaptability. Moreover, as industries increasingly prioritize personalization and uniqueness, this printing method positions itself as a frontrunner in meeting customer demands for tailored products.

The DTF Printing Process: Steps to Success

Understanding the DTF printing process is essential for anyone looking to harness its power for custom apparel printing. At the heart of this method lies a straightforward sequence of steps that ensures the reproduction of exquisite designs. First, the printing phase utilizes special DTF printers equipped with eco-solvent inks, which are designed to create vibrant images that remain durable even after multiple washes. This initial stage sets the tone for quality results that define the DTF transfer technology.

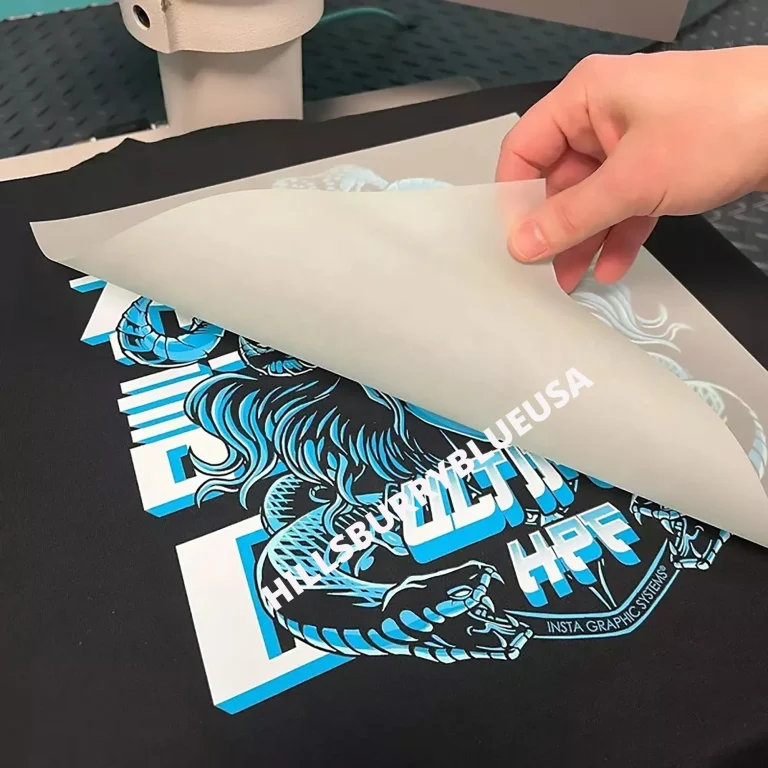

Next, the application of powder adhesive is crucial. This step entails evenly sprinkling adhesive powder onto the printed film while the ink remains wet. This not only helps in firmly bonding the design to the fabric during the heat transfer process but also aids in achieving the minimal texture that many artists desire. Finally, using a heat press to apply the design ensures that the transfer adheres perfectly to the garment, sealing in artistic detail and longevity.

Why DTF Transfers Are Revolutionizing Custom Apparel

The advantages of DTF transfers over traditional printing methods cannot be overstated. One of the primary reasons businesses are shifting towards DTF technology is the unparalleled detail and color fidelity it offers when producing intricate designs. This printing technique allows for a greater range of hues and gradients, making it perfect for artists who want to showcase their work on apparel. Furthermore, DTF transfers excel in producing vibrant visuals that stand out in today’s competitive fashion landscape.

Another significant advantage of DTF technology is its material versatility. Unlike other methods that may be restricted to cotton or polyester, DTF can effectively be used on a broader spectrum of fabrics. This flexibility means businesses can cater to diverse customer preferences, producing everything from stylish streetwear to sophisticated corporate branding. As the demand for unique apparel increases, DTF transfers empower brands to expand their inventory effortlessly.

Market Trends and Growth of DTF Transfers

As the custom apparel market evolves, DTF transfers have garnered attention for their alignment with key consumer trends. Businesses are increasingly drawn to this printing technique due to its cost-effectiveness and ability to meet orders with rapid turnaround times. This trend is particularly beneficial for startups and small enterprises looking to minimize upfront costs while offering personalized service. DTF printing enables these companies to react quickly to market demands, making it a viable option for meeting customer expectations and boosting brand loyalty.

Additionally, consumer preferences are leaning towards sustainability, and DTF processes often use environmentally friendly inks and materials. This aspect not only appeals to eco-conscious consumers but positions businesses favorably within competitive markets. As technology advances, the DTF transfer method is anticipated to become more efficient and accessible, paving the way for even greater adoption among printing companies.

Essential Equipment for DTF Transfers: What You Need

To embark on your journey with DTF transfers, it’s vital to have the right equipment that ensures optimal performance. At the heart of the setup is a specialized DTF printer that can handle transfer films and utilize eco-friendly inks. The choice of printer significantly impacts the quality of prints and the consistency of results. Investing in a high-quality DTF printer is essential for those looking to produce superior custom apparel that meets market demands.

Coupled with the printer, a reliable heat press machine serves as an integral part of the DTF printing process. This machine ensures even heat distribution and precise temperature control, vital for achieving the best adhesion between the transfer and fabric. Alongside these tools, quality adhesive powder is crucial for a successful transfer process, as it enhances the durability and longevity of the printed designs. The right setup empowers manufacturers to streamline their operations and deliver outstanding products.

The Future of DTF Transfers: Innovations Ahead

The future outlook for DTF transfers appears promising, with noteworthy advancements anticipated in technology and materials. Print quality is expected to improve as manufacturers refine their ink formulations and develop better transfer films, translating into even more vibrant and detailed graphics. These innovations will enhance the appeal of DTF printing for businesses that prioritize high-quality outputs in their custom apparel offerings.

Furthermore, as the demand for DTF technology continues to rise, market competition is likely to reduce prices for both equipment and materials. This shift will make DTF printing more accessible to newcomers and existing businesses alike. With continuous advancements, the process is also predicted to evolve into user-friendly solutions, paving the way for solo entrepreneurs and small shops to operate efficiently and create eye-catching designs that resonate with today’s consumers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique that allows high-quality designs to be printed onto transfer films for application onto fabrics. The process involves printing designs with eco-solvent inks, applying an adhesive powder while the ink is wet, and then using a heat press to bond the design with the garment. This results in vibrant, detailed prints that adhere well to various materials.

What equipment is required for DTF printing?

To start DTF printing, you’ll need a specialized DTF printer that can handle transfer film, a reliable heat press for applying transfers, and quality adhesive powder for optimal adhesion. Ensuring your equipment is compatible will enhance your DTF transfer operations and the overall quality of your custom apparel printing.

What are the advantages of using DTF transfers over traditional printing techniques?

DTF transfers offer several advantages, including the ability to produce intricate designs with high detail and color accuracy. Unlike traditional methods, DTF printing is versatile enough to work on various fabrics, including cotton and polyester. Additionally, DTF prints are durable, maintaining their vibrancy even after multiple washes, making them ideal for custom apparel.

Can DTF transfers be used for promotional items and personalized gifts?

Yes, DTF transfers are highly versatile and can be used to create various promotional items and personalized gifts. This technique allows businesses to produce unique and branded merchandise, such as t-shirts, tote bags, and aprons, with customized designs that stand out, making it a popular choice for promotional activities.

How does the DTF transfer process compare to screen printing?

The DTF transfer process differs significantly from screen printing in that it allows for quicker production of complex designs without the need for multiple screens. DTF printing handles vibrant colors and fine details more effectively, while also enabling quick turnaround times with no minimum quantities required for custom apparel. This flexibility is especially appealing to small businesses.

What trends are shaping the future of DTF transfers in the printing industry?

The future of DTF transfers is characterized by advancements in technology, leading to enhanced print quality and lowered costs. As the demand for custom apparel grows, we can expect innovations such as improved ink formulations, user-friendly software, and accessible production techniques, making DTF printing an increasingly viable option for both businesses and hobbyists.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A modern printing method that transfers high-quality designs onto fabrics using special transfer films and heat. |

| The DTF Printing Process | 1. Printing on transfer film with eco-solvent inks. 2. Applying adhesive powder over wet ink. 3. Heat pressing to bond the design to fabric. |

| Advantages of DTF Transfers | – High detail and color accuracy. – Material versatility. – Durable prints that withstand multiple washes. |

| Market Trends | Increasing popularity in small businesses due to lower costs and quick turnaround for custom apparel. |

| Applications | Custom apparel, promotional items, and personalized gifts. |

| Required Equipment | DTF printer, heat press, and quality adhesive powder. |

| Future Outlook | Growth in print quality, decreased costs, and user-friendly solutions are anticipated. |

Summary

DTF transfers represent a groundbreaking advancement in the field of garment decoration. This guide has covered the essential information about DTF transfers, from their definition and advantages to the applications and future trends. The ability of DTF transfers to deliver high-quality results on various fabrics means they are poised to play a pivotal role in the garment printing industry. By embracing DTF transfers, businesses can significantly enhance their product offerings, cater to diverse consumer needs, and stay competitive in a rapidly evolving market.