DTF transfers, or Direct-to-Film transfers, are transforming the landscape of printing with their impressive adaptability and brilliance. This innovative printing method applies designs directly onto a special film, which are then transferred to a variety of fabrics using a heat press application for DTF. Unlike traditional methods, the DTF printing process allows for vibrant colors and intricate details that can withstand multiple washes, making it perfect for both small-scale crafts and large productions. Furthermore, DTF printing advantages include its compatibility with both cotton and blended materials, setting it apart from sublimation, which is typically limited to polyester fabrics. In this guide, we’ll delve into all aspects of DTF transfers, providing valuable tips and comparisons to help you maximize your creative projects and business opportunities.

Direct-to-Film printing, commonly abbreviated as DTF, is an emerging technology that combines high-quality imagery with versatility across fabric types. This method enhances the customization possibilities for creators and businesses alike, as it allows for the printing of colorful designs directly onto a film for heat application. When examining the recent advancements in this printing technique, it’s essential to note that DTF printing is not only cost-effective but also offers durability and vibrancy that rivals other printing options, such as sublimation and screen printing. With its ability to cater to a wide range of materials, the heat press application for DTF has become a staple for those looking to push the boundaries of traditional printing methods. As we explore the potential of this exciting printing technology, we’ll uncover the unique benefits and practical applications that DTF transfers bring to the forefront.

Understanding the DTF Printing Process

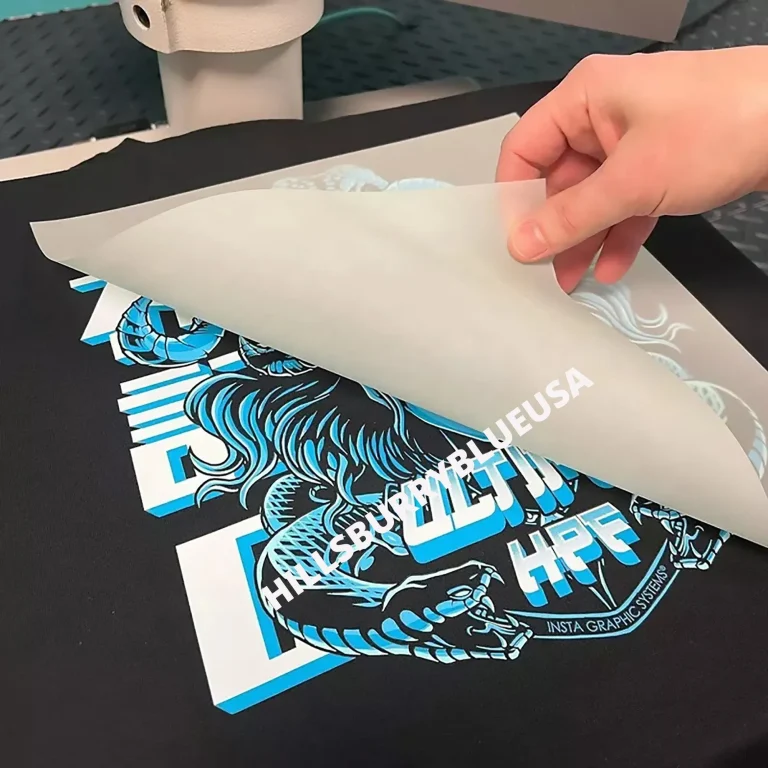

The Direct-to-Film (DTF) printing process is a transformative approach that simplifies the creation of vibrant designs on a variety of fabrics. Starting with the application of specialized inks onto a unique transfer film, the process allows artists and businesses to bring their creative visions to life. With DTF, you can print detailed graphics with stunning colors that are ready to be transferred onto the chosen fabric. The film is then subjected to a heat press application, which bonds the design to the fabric, resulting in a durable and eye-catching finish.

One of the standout features of DTF printing is its versatility; it works exceptionally well with both cotton and blended materials, in contrast to sublimation that primarily caters to polyester fabrics. This characteristic opens up new avenues for custom apparel and merchandise, enabling creators to experiment with various fabrics without losing quality. As you get deeper into the DTF printing process, you’ll soon realize its efficiency and effectiveness in producing high-quality results.

Advantages of DTF Transfers Over Traditional Methods

DTF transfers provide numerous advantages that make them an appealing choice for both hobbyists and commercial enterprises. For starters, cost-effectiveness stands out prominently; many businesses opt for DTF technology to reduce overhead costs associated with traditional printing methods. Equipment and material costs are lower, allowing for low minimum order quantities. This advantage is particularly beneficial for small business owners and craft enthusiasts who may not have extensive budgets.

Moreover, DTF printing boasts exceptional color vibrancy and durability. The prints maintain their quality and sharpness even after repeated washes, which is a crucial factor for commercial apparel. Unlike screen printing and sublimation, where limitations on fabric types may affect design options, DTF’s compatibility with various materials broadens the scope of what creators can achieve, making it ideal for custom projects on a larger scale.

Comparing DTF Printing and Sublimation

The comparison between DTF printing and sublimation has been a hot topic within the crafting community. Traditional sublimation works well primarily on polyester materials, which limits the types of items that can be customized. In contrast, DTF printing extends its capabilities to cotton and blends, making it a more flexible choice for different fabric projects. This adaptability not only gives creators more options but also enhances the overall appeal of custom printed products.

Another significant difference lies in the application process. While sublimation requires the heat transfer process to enable the dye to bond with the fabric fibers, DTF uses a different approach. It prints onto a film that is heat-pressed onto the material. This method allows for more intricate designs and vibrant results, ensuring that the printed images pop. Creatives and businesses need to weigh these factors when choosing between the two methods, considering the specific needs of their projects.

Tips for Successful DTF Transfers

To achieve the best results with DTF transfers, a few tips can go a long way. Firstly, selecting a reliable printer that supports high-quality DTF printing is crucial. Not all printers are created equal; thus, investing in a machine designed for this purpose will enhance your print quality and ease of use. Brands like EazyDTF are known for their quality printers dedicated to optimizing DTF production, making them worth considering.

Additionally, familiarizing yourself with heat press techniques is vital. The right temperature settings and pressure levels can significantly affect the outcome of your print. Too much heat can damage the film or fabric, while insufficient heat may result in poor adhesion. Experimenting with different settings will help you find the optimal conditions for your projects, allowing for vibrant and long-lasting prints.

Exploring the Latest Developments in DTF Technology

The landscape of DTF printing is constantly evolving, with new technology and services emerging to accommodate the growing demand. For example, the recent launch of DTFPrinter.com has made it notably easier for hobbyists to enter the world of DTF printing. By eliminating high minimum orders, this platform allows individuals to experiment without a heavy financial commitment. This shift not only democratizes access to DTF technology but also encourages more creative explorations.

Additionally, notable companies like Snuggle and EazyDTF are expanding their services to keep pace with the increasing popularity of DTF. Snuggle’s new trade service, capable of producing over 10,000 A4-format transfers daily, illustrates how commercial capacities are being ramped up to meet demand. Meanwhile, EazyDTF’s investment in large-format DTF printing technology underscores the importance of scalability and efficiency in the printing process.

Getting Started with DTF Printing

Getting started with DTF printing is an exciting venture that requires a few essential steps. Begin by choosing a reliable printer that specializes in Direct-to-Film printing. Research and understand the characteristics of different models, such as print resolution and compatibility with materials, to find one that meets your specific needs. Reputable suppliers offer printers geared toward DTF, ensuring you have the right tools for creating vibrant designs.

In addition to a quality printer, securing high-quality DTF film and inks is crucial to achieving optimal results. Look for vendors known for their reliable products, as the quality of your materials directly affects the vibrancy and durability of your prints. Lastly, invest time in mastering heat press techniques and familiarize yourself with design software to produce eye-catching graphics. With these steps in place, you’ll be well on your way to exploring the exciting possibilities of DTF transfers.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, short for Direct-to-Film transfers, involve printing designs onto a special film that is then heat pressed onto various fabrics. This innovative DTF printing process allows for the creation of vibrant and detailed graphics that adhere well to a variety of materials, making them ideal for both custom and large-scale print projects.

What are the advantages of DTF printing compared to sublimation?

DTF printing has several advantages over sublimation printing. Most notably, DTF transfers can be applied to a wider range of fabrics, including cotton and blends, while sublimation primarily works best on polyester fabrics. Additionally, DTF prints offer sharp, vibrant colors that remain durable even after multiple washes.

How do I apply DTF transfers using a heat press?

Applying DTF transfers with a heat press involves a few steps: First, preheat your heat press to the recommended temperature (usually around 330°F). Place the DTF transfer on the fabric and cover it with parchment paper. Press with firm pressure for the suggested time (typically 10-15 seconds), then let it cool before peeling away the film to reveal the design.

What features should I look for in a DTF printer?

When selecting a DTF printer, consider factors like print quality, compatibility with specialized DTF inks, and the ability to handle various film types. Look for printers that offer user-friendly software and those capable of producing high-resolution prints to achieve vibrant DTF transfers.

Are DTF transfers washable and durable?

Yes, DTF transfers are designed to be durable and withstand multiple washes without fading. Recent studies have shown that when applied correctly using proper heat and pressure, DTF prints maintain their vibrancy and integrity, making them an excellent choice for long-lasting designs.

What is the difference between DTF printing and screen printing?

DTF printing and screen printing differ primarily in the application process and the types of designs they can produce. DTF transfers allow for colorful and intricate designs to be printed directly onto a film and then transferred, providing greater detail. In contrast, screen printing is better suited for larger quantities of simple designs, requiring more setup and manual labor.

| Key Point | Details |

|---|---|

| What Are DTF Transfers? | A method where designs are printed on special film that adheres to fabrics through heat application. |

| Why Choose DTF? | DTF offers versatility across fabric types, vibrant colors, and cost-effective solutions with low minimum order requirements. |

| Latest Developments | Includes the launch of DTFPrinter.com, Snuggle’s new trade service, and EazyDTF’s expansion for enhanced production capabilities. |

| DTF vs. Sublimation | DTF is more versatile than sublimation, as it works effectively on cotton and blended fabrics. |

| Durability Concerns | Ongoing tests are evaluating the long-term performance and removability of DTF transfers, influencing consumer decisions. |

| Getting Started with DTF Transfers | Requires a reliable printer, high-quality film and inks, knowledge of heat press techniques, design software, and experimentation. |

Summary

DTF transfers have revolutionized the printing process, making them an ideal choice for both crafters and business owners. This innovative printing method allows for vibrant, durable designs on a wide variety of fabrics, far surpassing traditional techniques like sublimation. The recent advancements in DTF technology, such as accessible printing platforms and enhanced production capacities, make it an opportune time to engage with DTF transfers. By understanding the advantages and steps to get started, individuals can harness the potential of DTF printing, unleashing their creativity like never before.